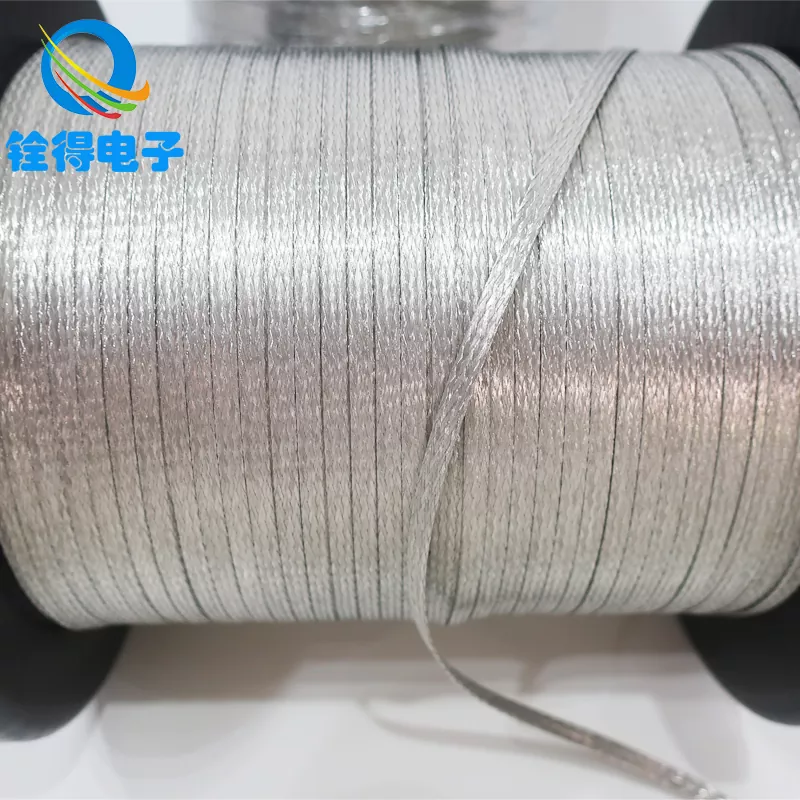

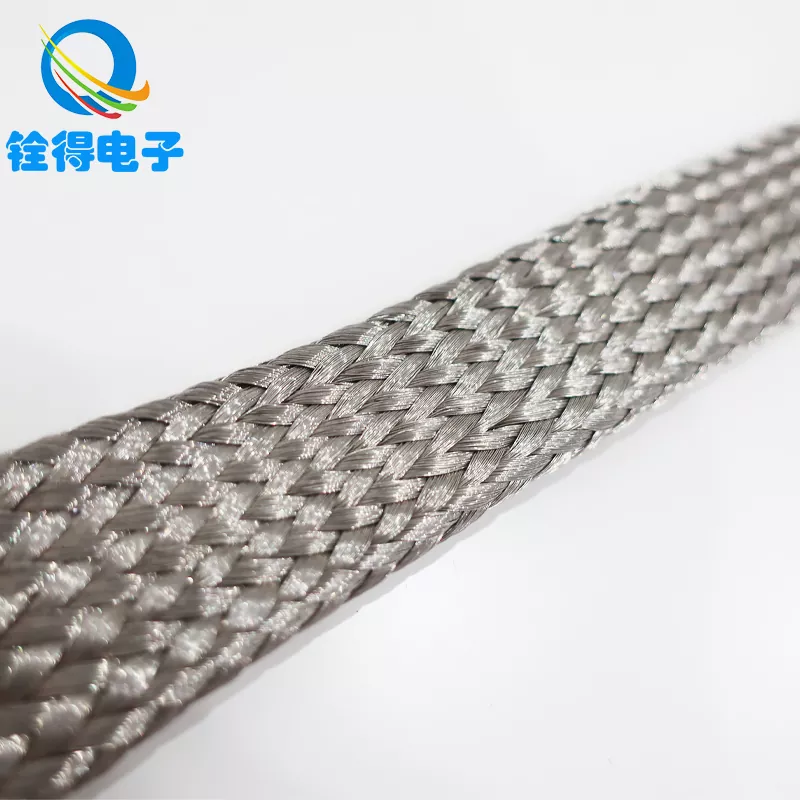

Tinned Copper Braided Wire

Send Inquiry

The tinning of tinned copper braided wire is mainly to prevent copper oxidation. Because copper is easily oxidized in the air, the generated copper oxide will increase the resistance of the circuit and affect the conductivity. The tinned layer is like a protective film, which can effectively isolate the contact between copper and air, moisture, etc., thereby extending the service life of the copper braided wire. In appearance, the tinned copper braided wire is bright silver and more beautiful. In the connection of electronic equipment, tinned copper braided wire can not only provide good conductivity, but also be used for some fine connection parts with high appearance requirements by virtue of its appearance advantages. For example, in some circuit connections of the computer motherboard, tinned copper braided wire can ensure the quality of signal transmission while making the motherboard look neater. It also has good solderability, which is more convenient to use in electrical connection scenarios that require welding. For example, when making some small electronic products or repairing electrical appliances, the use of tinned copper braided wire can make the welding process smoother. Quande provides a variety of specifications of braiding, and more favorable prices for large quantities.