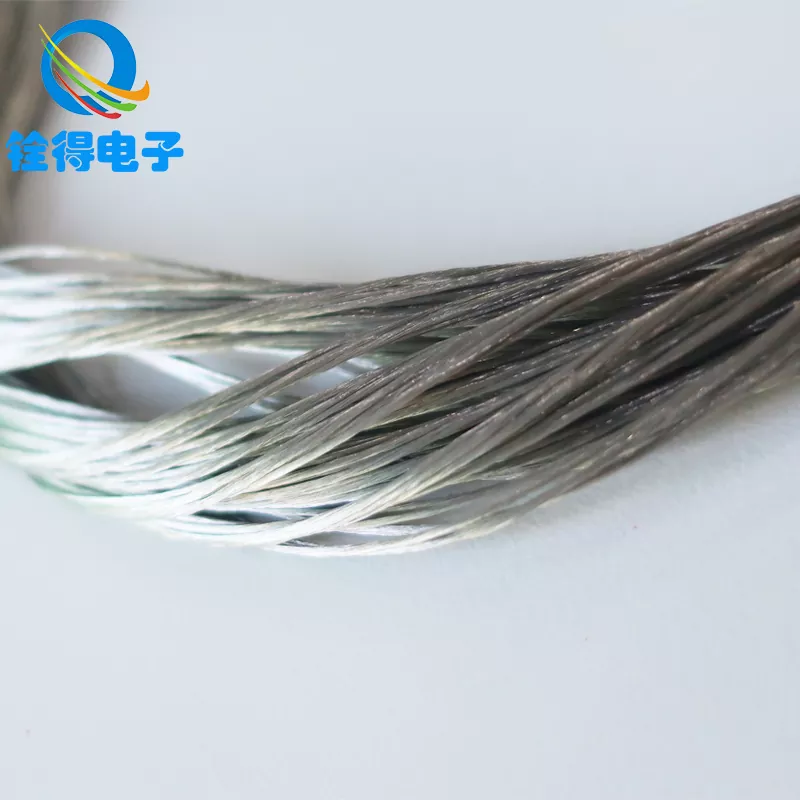

Tinned Copper Stranded Wire

Send Inquiry

Tinned copper stranded wire is a wire with a layer of tin on the surface of copper stranded wire. It has the good conductivity and mechanical properties of copper, and the tin layer improves the anti-oxidation and anti-corrosion ability. It is often used as a conductive material in electronic and electrical equipment, as well as in power transmission and communication lines that require corrosion resistance. Bare copper stranded wire is a wire made of multiple bare copper wires.

Tinned copper stranded wire has strong flexibility: the structure of multiple copper wires twisted together gives it a certain flexibility. Compared with a single copper rod, it is easier to bend and operate, and is convenient for laying in various complex installation environments, such as connecting lines inside distribution cabinets or laying electrical lines in buildings.

Tinned copper stranded wire has high mechanical strength. By twisting, the mechanical strength of the stranded wire is increased compared to that of a single copper wire. It can withstand a certain amount of tension and tension, and in scenes such as overhead transmission lines, it can resist external forces caused by natural factors such as wind and ice.

In order to prevent damage to products during transportation, Quande manufacturers also attach great importance to packaging. Multi-layer packaging ensures that the products are not damaged during transportation.