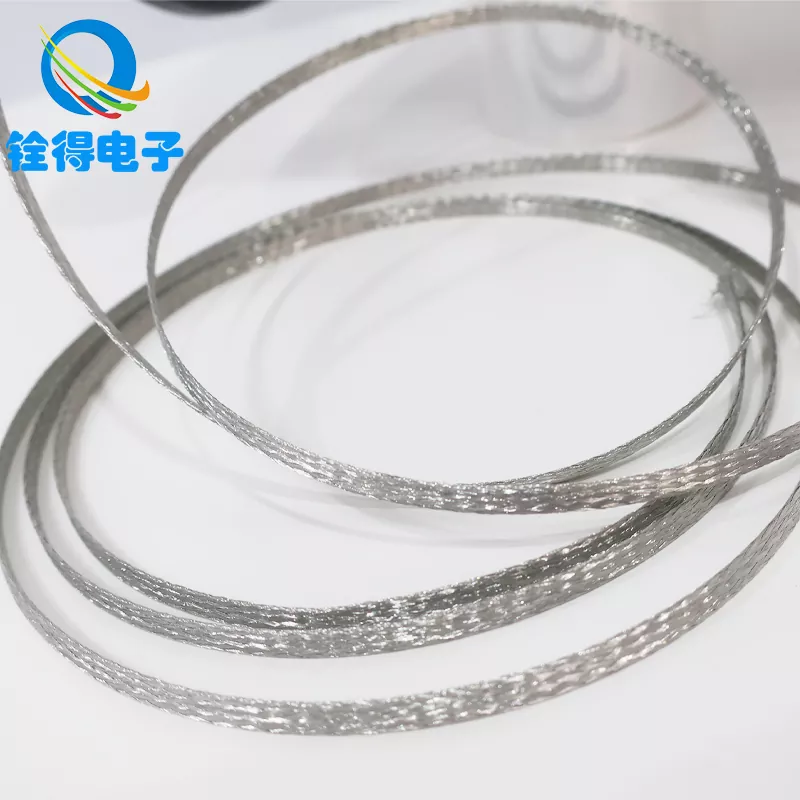

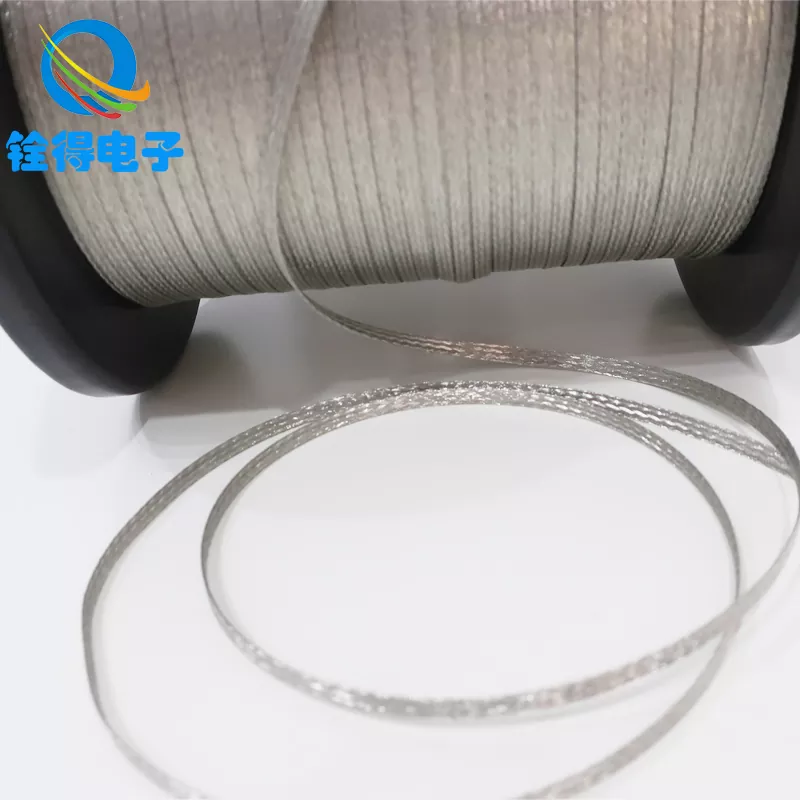

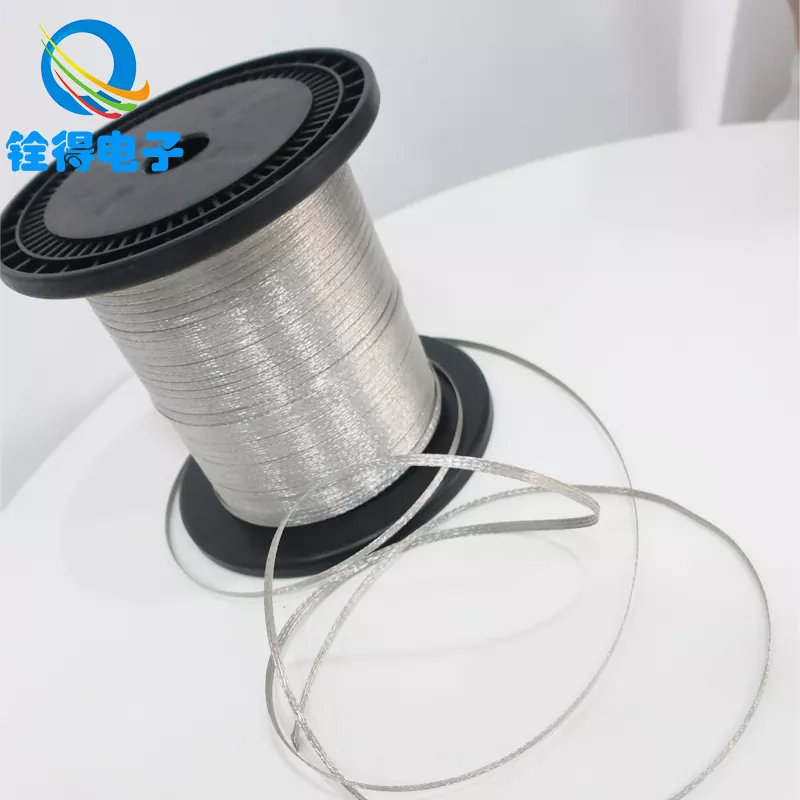

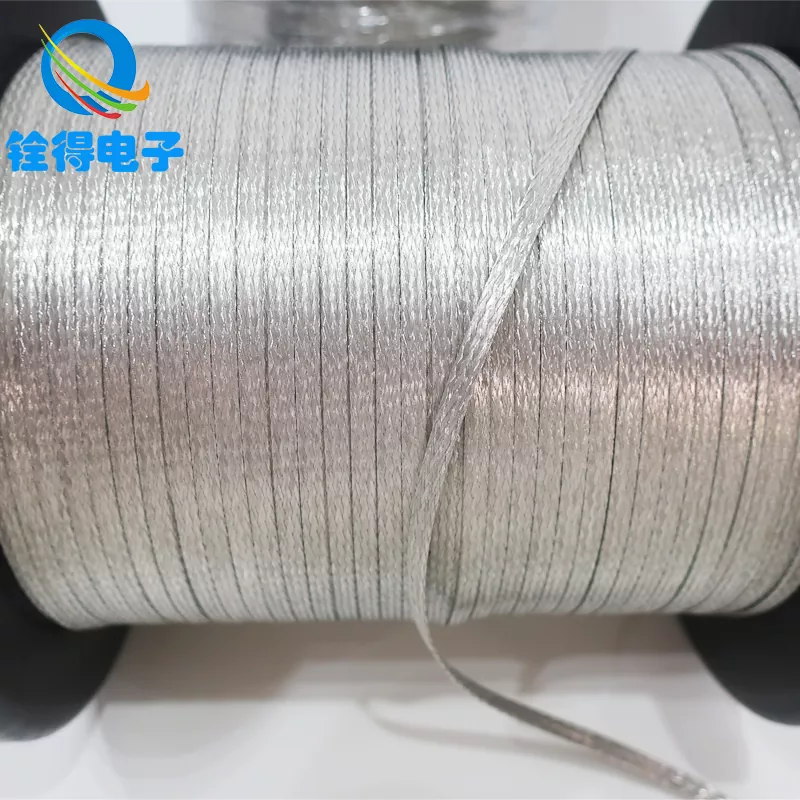

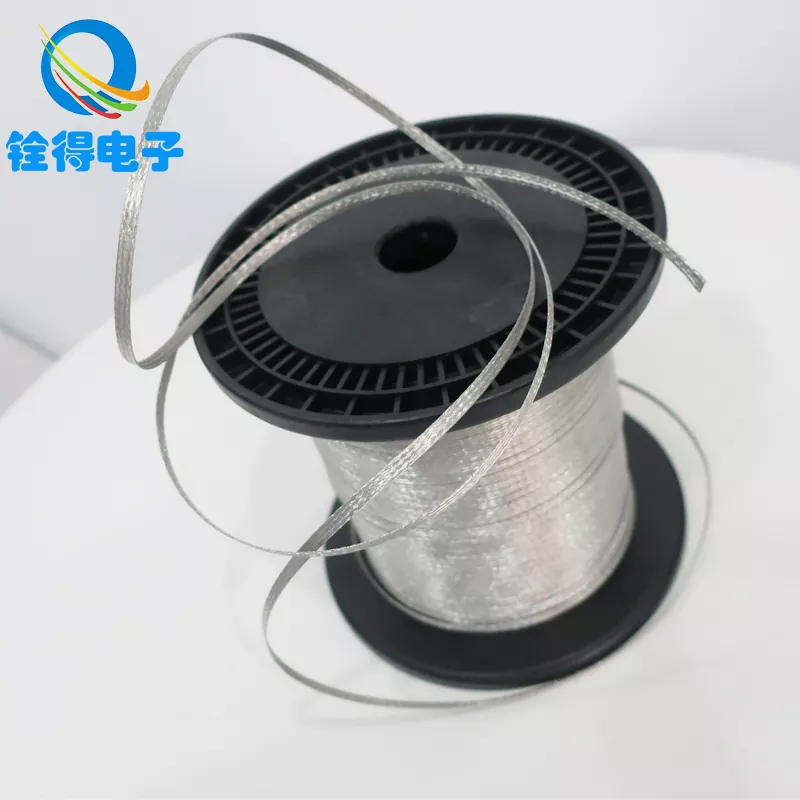

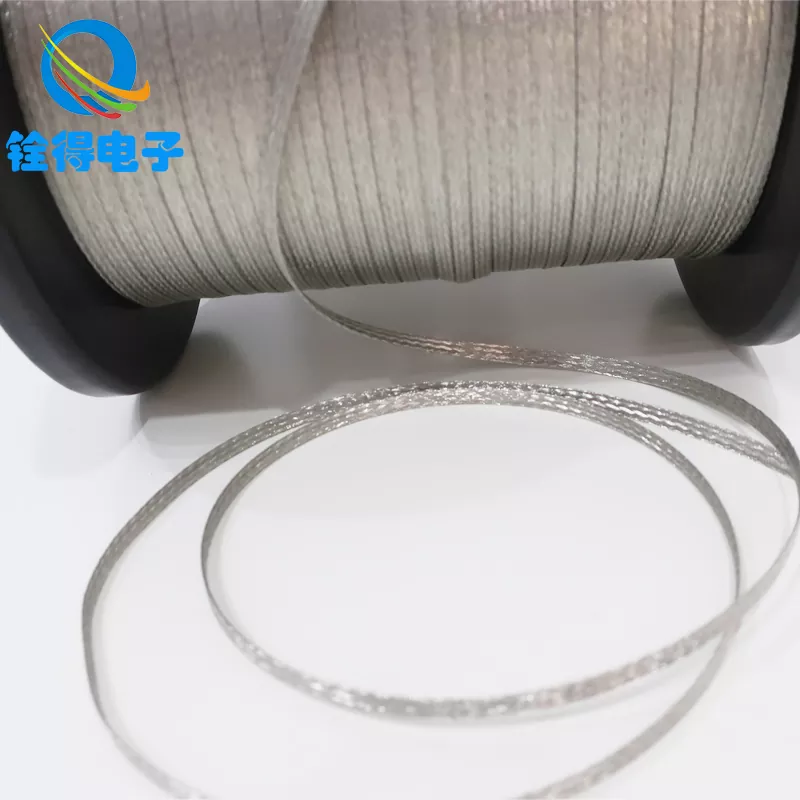

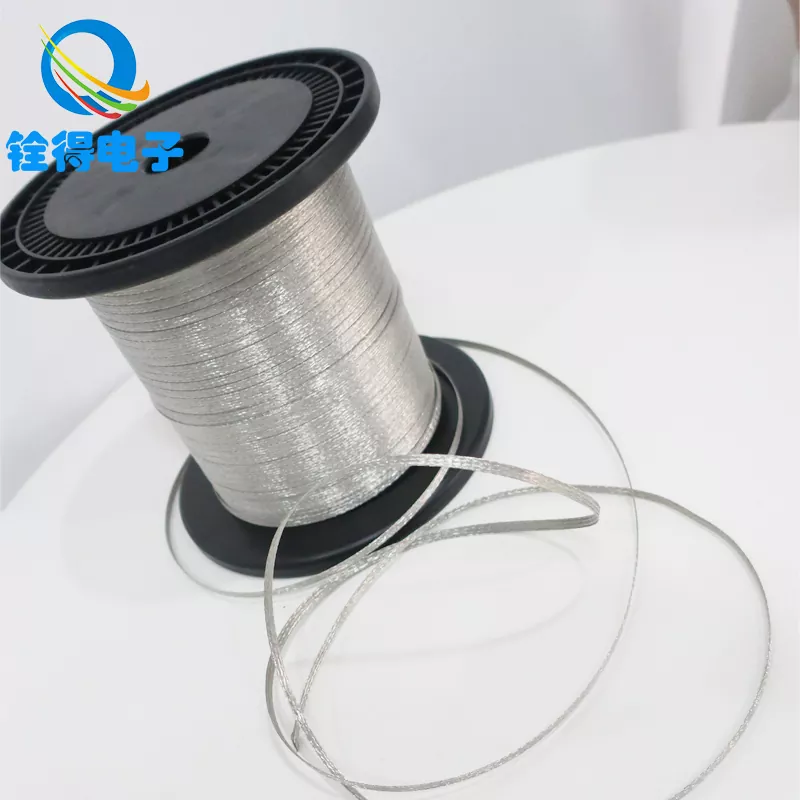

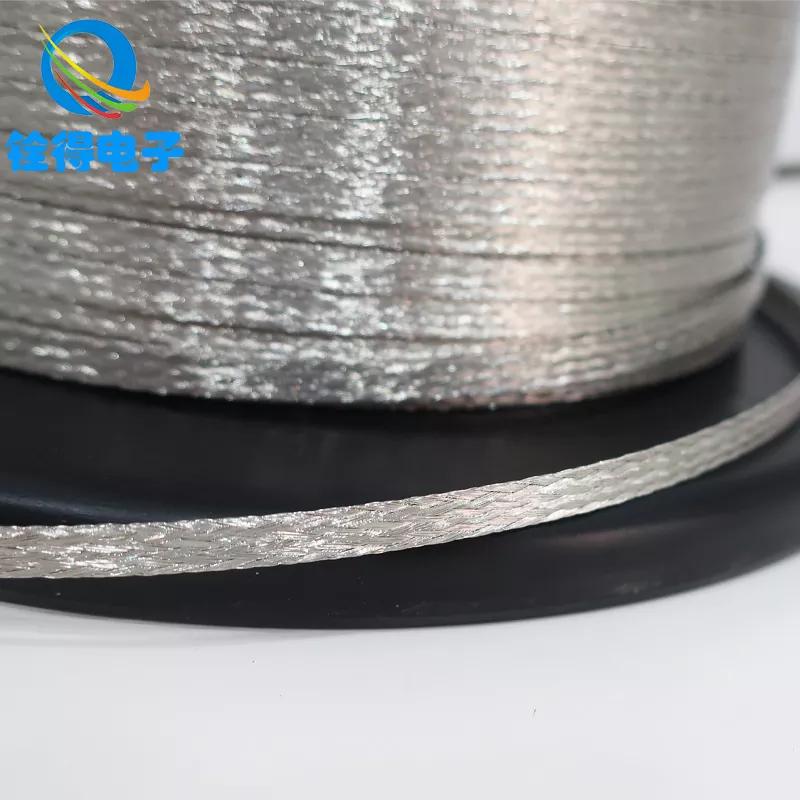

Tinned Copper Braided Mesh Tube

Send Inquiry

--Production process: First, copper-clad aluminum wire is prepared, then drawn to the appropriate wire diameter, followed by weaving into a mesh tube shape using a weaving machine, and finally subjected to tin plating to enhance corrosion resistance and oxidation resistance.

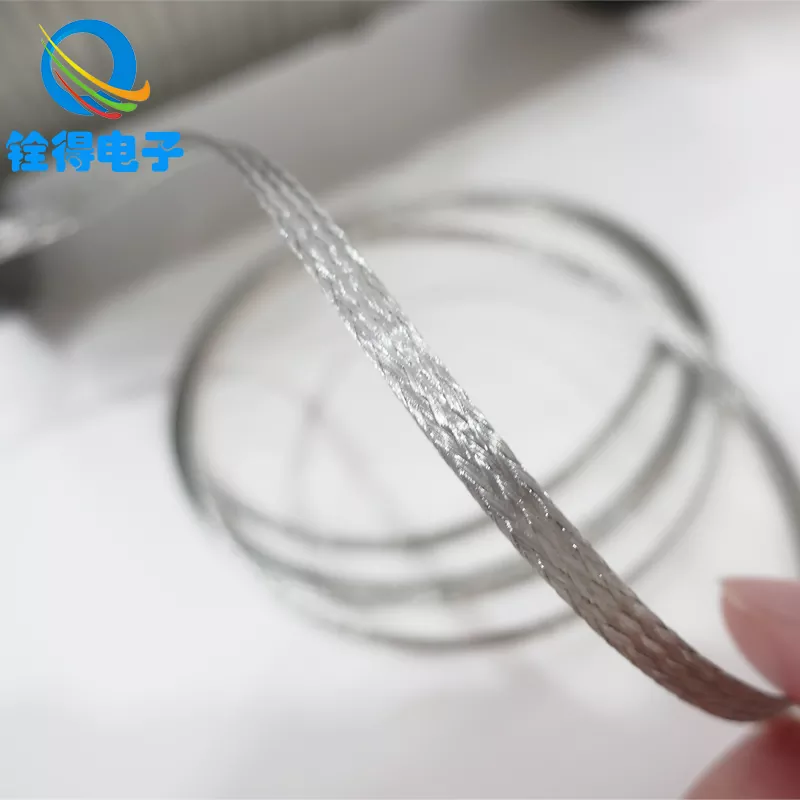

--Material Composition: Based on copper-clad aluminum wire, a layer of tin is applied to its surface through a hot-dip tinning process. Copper-clad aluminum wire consists of a copper layer concentrically wrapped around the outer surface of an aluminum core wire, forming a strong atomic metallurgical bond between the copper layer and the core wire.

Tin-plated copper-clad aluminum wire primarily consists of an aluminum core wire, a copper cladding layer, and a tin coating. The aluminum core wire provides basic conductivity, the copper cladding layer enhances conductivity and oxidation resistance, and the tin coating improves corrosion resistance, oxidation resistance, weldability, and contact performance. It is then woven into a tin-plated copper-clad aluminum mesh tube using a weaving machine. Tin-plated copper-clad aluminum braided mesh tubes combine the characteristics of tin-plated copper and copper-clad aluminum.

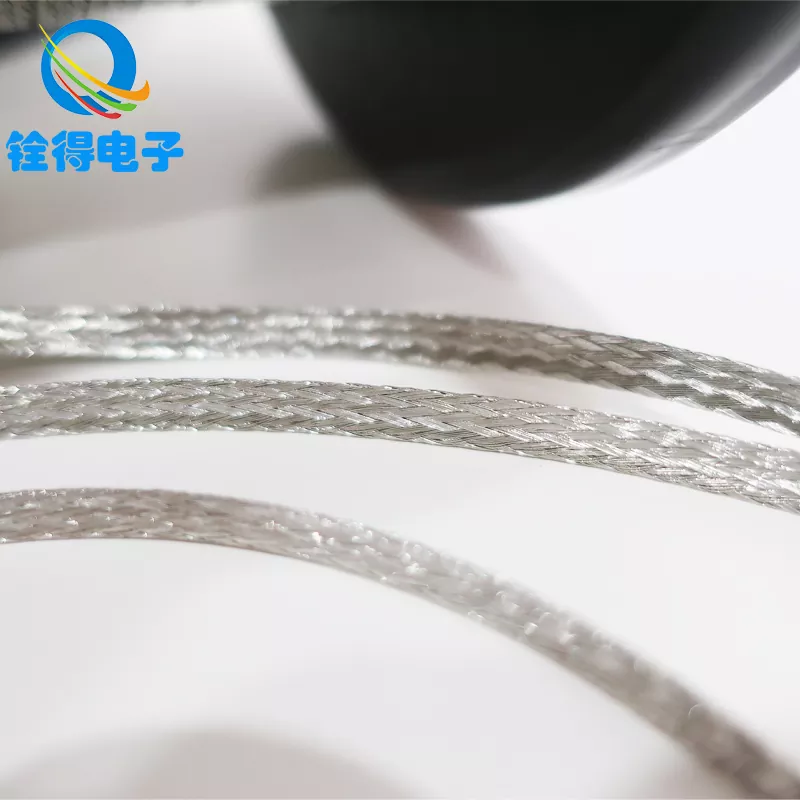

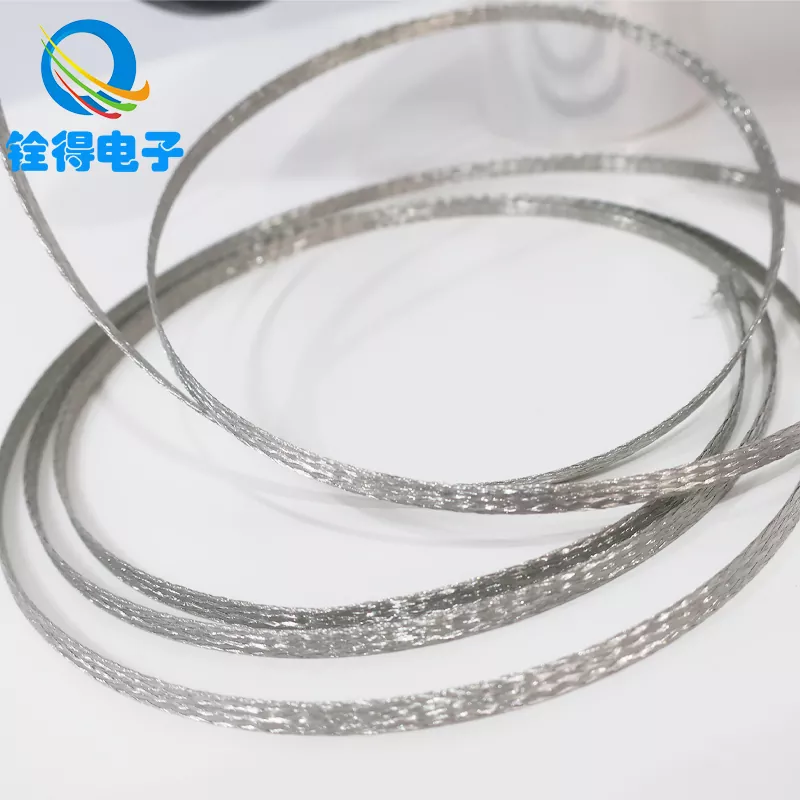

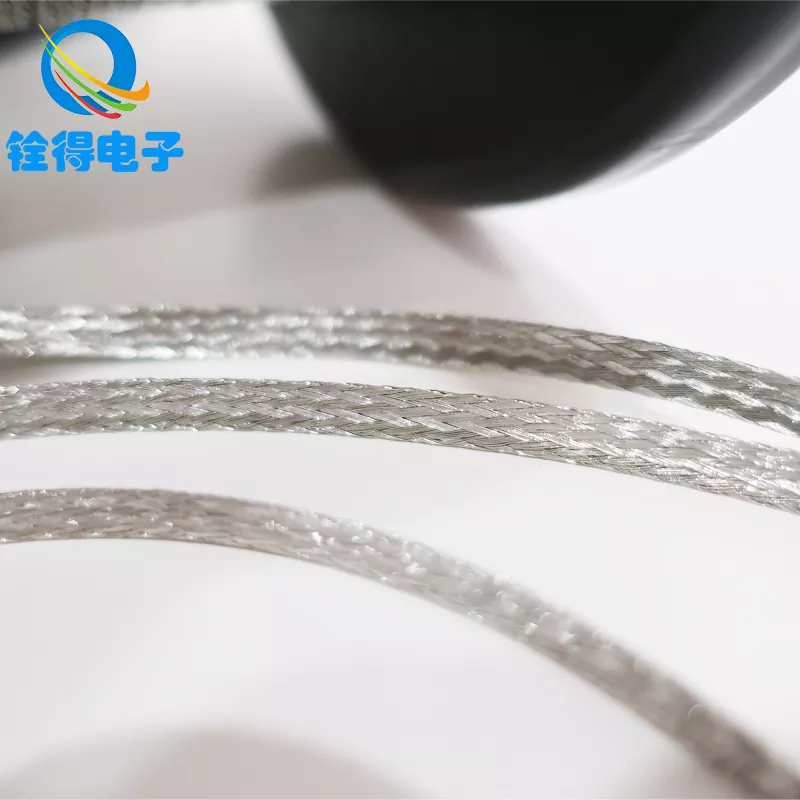

Tin-plated copper-clad aluminum braided mesh tubes have a braided mesh structure, with braiding density adjustable according to requirements. Common specifications include 120C, 144C, and 168C, among others, with other specifications available upon request.

The selection of weaving density for tin-plated copper-clad aluminum woven mesh tubing should be based on the specific application scenario and core requirements, primarily considering the following factors:

1. Shielding performance requirements

- For use in environments with strong electromagnetic interference (such as industrial equipment or high-frequency communication scenarios), a high weaving density (e.g., 144C or above) is required. A densely woven structure can more effectively block electromagnetic/radio frequency interference and enhance shielding efficiency.

- For basic shielding or use in low-interference environments (e.g., internal wiring of general electronic devices), medium to low densities (e.g., 120C or below) are sufficient to meet requirements while reducing costs.

2. Flexibility and installation requirements

- High-density mesh tube structures are more compact and have relatively lower flexibility, making them suitable for simple wiring paths with few bends.

- If frequent bending or adaptation to complex wiring shapes is required (e.g., at corners in automotive wiring harnesses), medium to low density is recommended, as it is easier to bend and more convenient to install.

3. Cost Control

- Higher weaving density results in greater raw material consumption and processing difficulty, leading to higher costs. Under the premise of meeting performance requirements, appropriate density can be selected based on budget to avoid unnecessary waste from overly pursuing high density.

4. Protection and Durability

- High-density mesh tubing offers superior tensile strength and abrasion resistance. For environments prone to friction or impact (e.g., external wiring harnesses on industrial equipment), it is recommended to prioritize high-density options for enhanced protection; in standard environments, medium to low density is sufficient to meet basic durability requirements.