Enamelled Copper Braided Wire

Send Inquiry

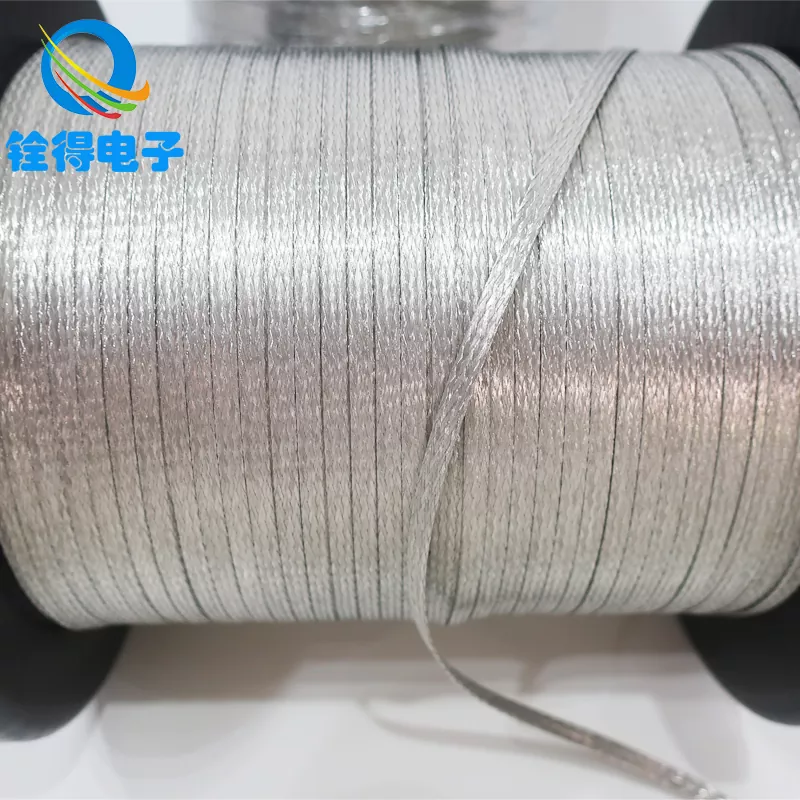

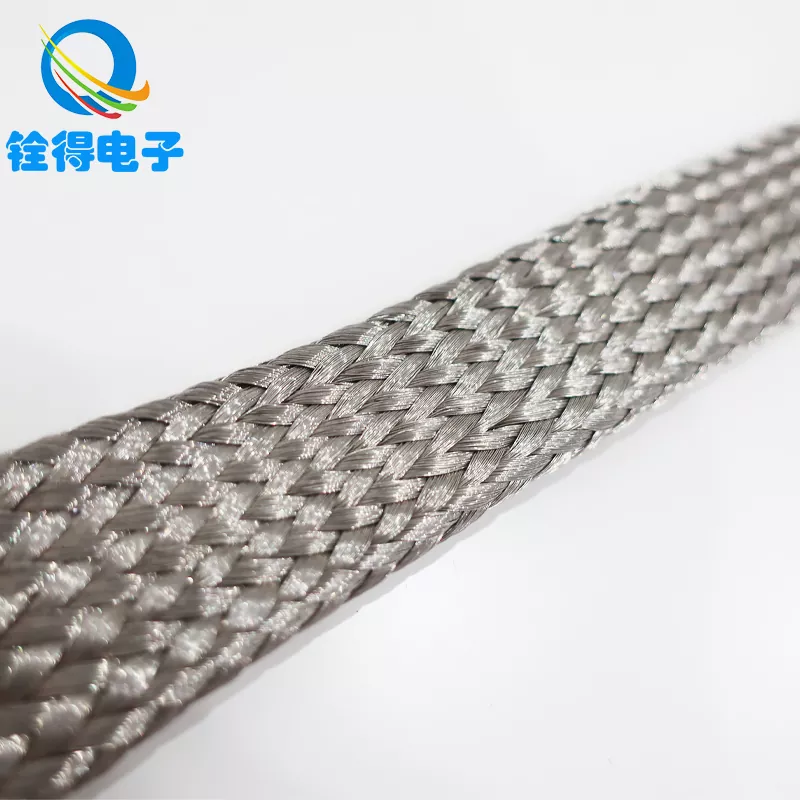

Enamelled Copper Braided Wire is a wire woven from fine enameled copper wire. It has good conductivity and can transmit current efficiently. The enameling treatment is to coat the surface of the copper braided wire with a layer of insulating paint. This layer of paint has many important functions. On the one hand, it provides good insulation performance, can prevent current leakage, avoid short circuit, and make the enameled copper braided wire safe to use in some electrical equipment with insulation requirements, such as motors, transformers and other internal windings. On the other hand, this layer of paint can also play a certain protective role, preventing the copper braided wire from being oxidized and corroded, thereby extending the service life of the wire. The enameled copper braided wire produced by Quande has a fine braiding density, a smooth surface, no burrs, and no cuts in the middle. Various copper braided belt models can be produced according to customer drawings or needs. The packaging method adopts axle packaging.

The copper content of the enameled copper wire used by Quande is as high as 99.5% or more. The selection of raw materials is extremely strict, and the best and most reliable materials are used to ensure the high quality of the product from the source.