Square Copper Braided Wire

Send Inquiry

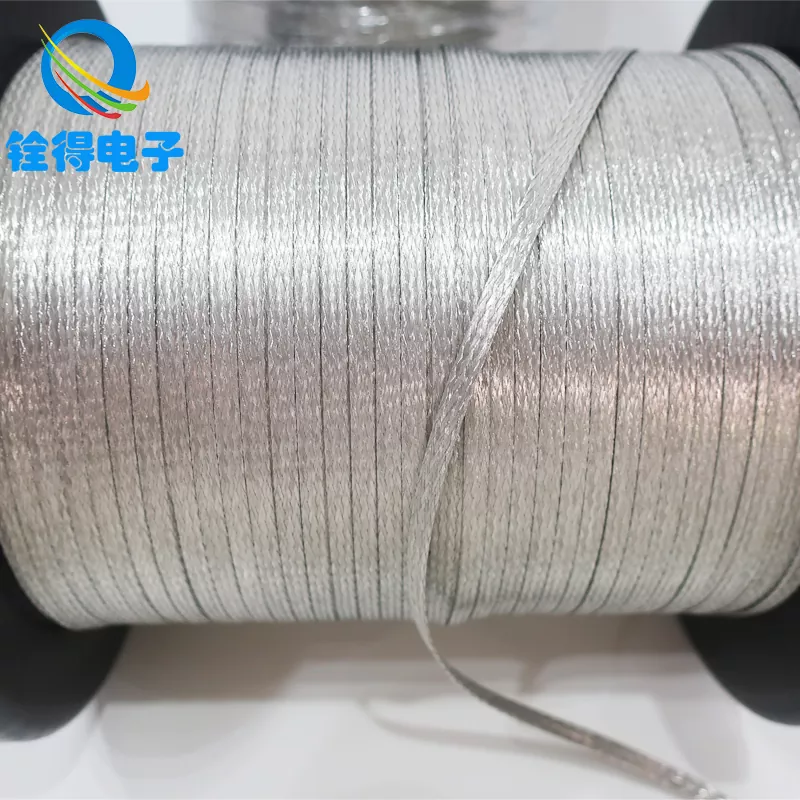

This specific braiding machine is quite special and meets the market demand for square braided wires to a great extent. Various models and sizes can be made. Square copper braided wire supports full parameter customization of wire diameter, width, thickness, cross-sectional area, and braiding density. Commonly used copper wire diameters are 0.04mm, 0.05mm, 0.06mm, 0.07mm, 0.08mm, 0.09mm, 0.10mm, 0.12mm, 0.15mm and other different sizes, which meet the special process requirements of most people for different purposes. Individual high-tech customization will use extremely fine round copper wires with wire diameters of 0.025mm and 0.03mm.

Square copper braided wireIn the field of electrical connection, traditional round braided wire can no longer meet the dual challenges of space utilization and performance in complex working conditions. Square copper braided wire came into being, redefining the new standard of electrical connection with breakthrough structural design and excellent performance, and becoming an ideal choice for high-end equipment and precision engineering!

The square cross-section of the square copper braided wire bids farewell to the redundant space occupied by traditional round cables, and the flat and regular shape perfectly adapts to the narrow wiring environment. Whether it is the wiring in the dense distribution cabinet, the compact layout of the battery module of new energy vehicles, or the ultra-thin space of aerospace equipment, it can efficiently utilize every inch of space and help the system achieve lightweight and miniaturized design.

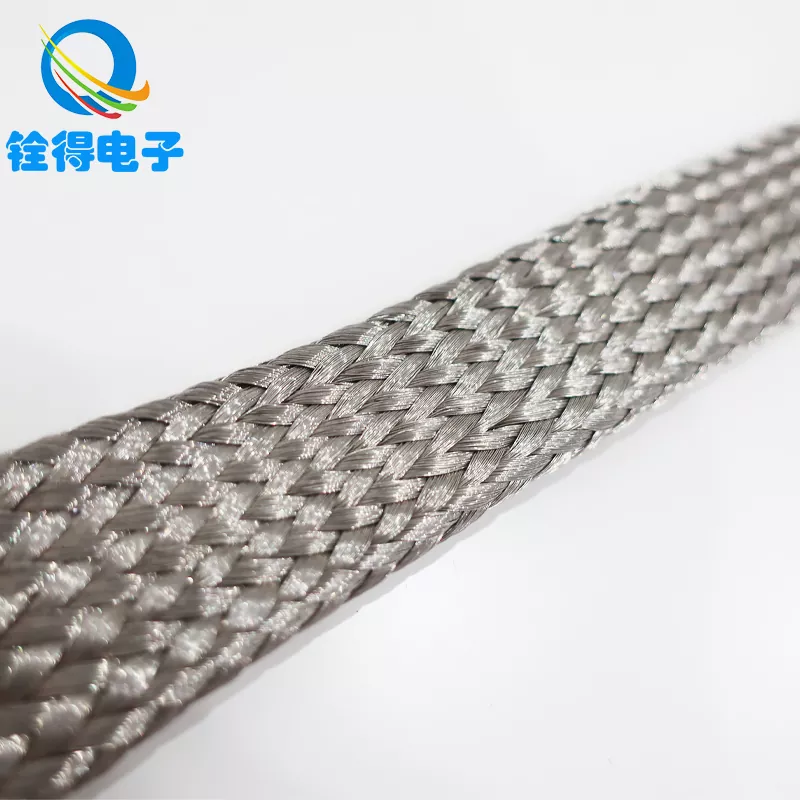

The square copper braided wire selects more than 99.968% high-purity oxygen-free copper wire and adopts a precise cross-weaving process to make the current transmission path shorter and the contact area larger. Compared with the same specification round braided wire, the resistance is reduced by 15%, which effectively reduces the heat loss, ensures the stable transmission of high-power current, and provides strong power support for industrial automation, rail transportation and other fields.

The multi-layer braided structure of square copper braided wire gives the square copper braided wire excellent flexibility and anti-bending ability. Even in harsh environments with frequent vibration and torsion (such as construction machinery and wind power equipment), it can maintain structural integrity and eliminate the risk of breakage. The surface tinning/silver plating further improves the anti-oxidation and anti-corrosion properties, and extends the service life by 30%.

What are the characteristics of square braided copper wire:

--Good conductivity: Square copper braided wire is made of high-purity copper materials, such as oxygen-free copper, with a copper content greater than or equal to 99.965%, and has excellent conductivity, which can ensure stable and efficient transmission of current.

--Good flexibility: Square copper braided wire is woven from multiple strands of fine copper wire, with a soft texture, can be bent and twisted, can adapt to various complex installation environments and connection requirements, and is not easy to break due to bending.

--Good heat dissipation: Due to the square structure and weaving method, the square copper braided wire has a large surface area, which is conducive to heat dissipation, can effectively reduce the heat generated by the passage of current, and improve the safety and stability of use.

--Strong fatigue resistance: Square copper braided wire can maintain good performance in long-term use and frequent vibration environments, and is not prone to fatigue fracture, which extends its service life.