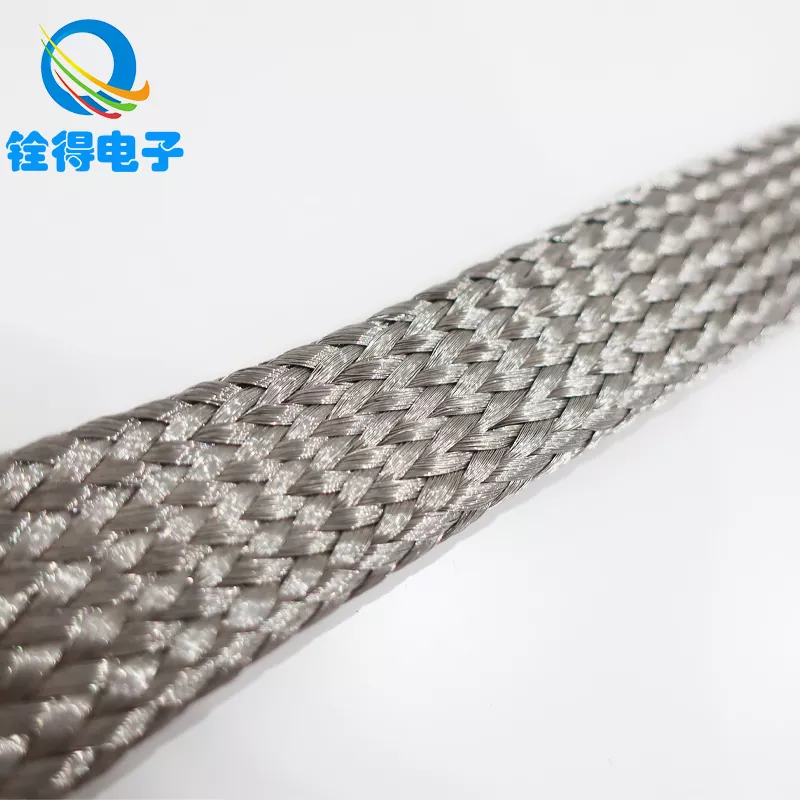

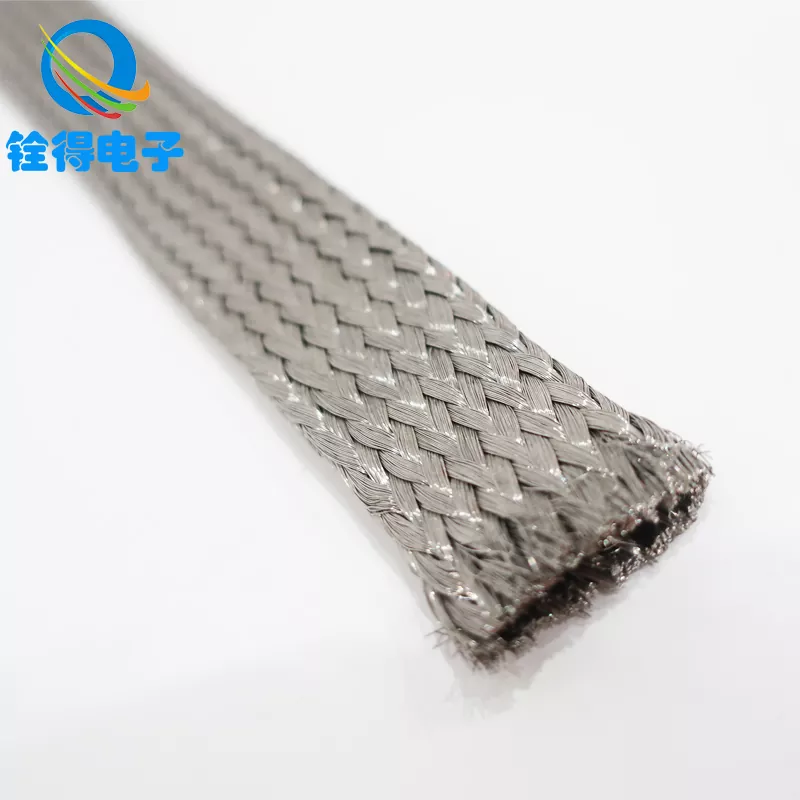

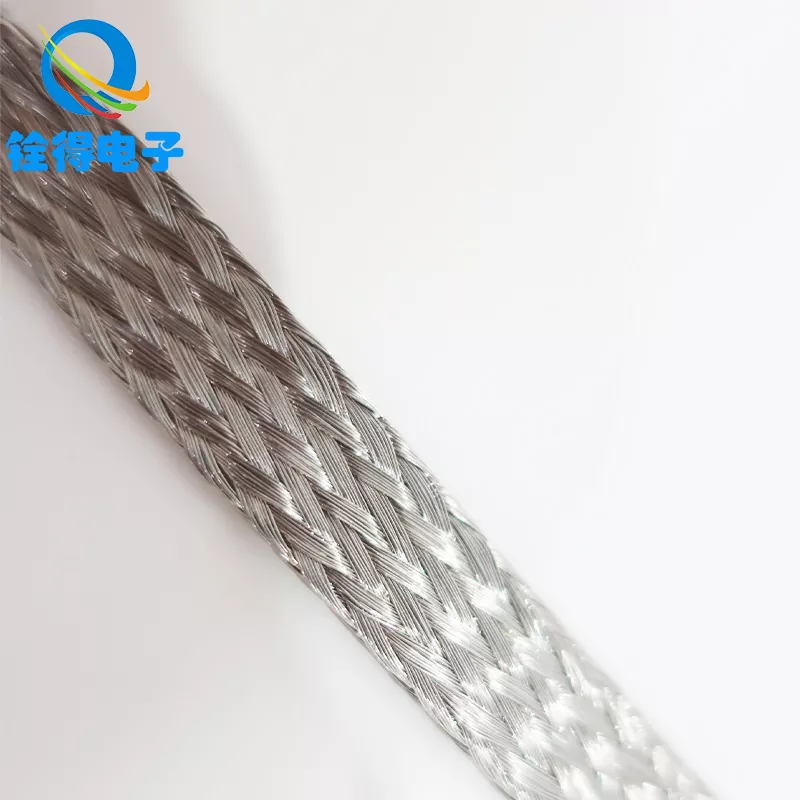

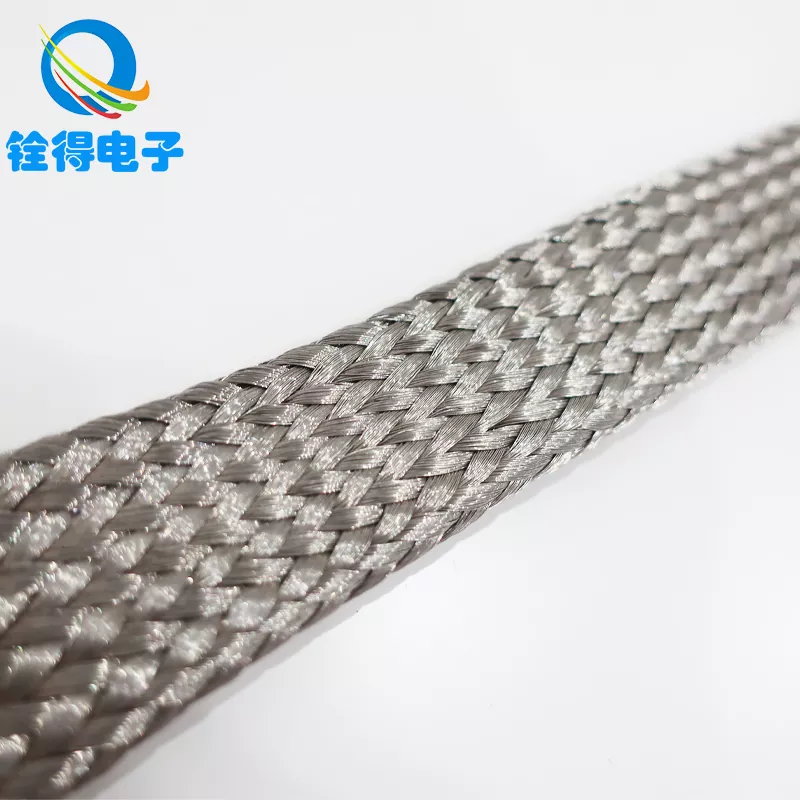

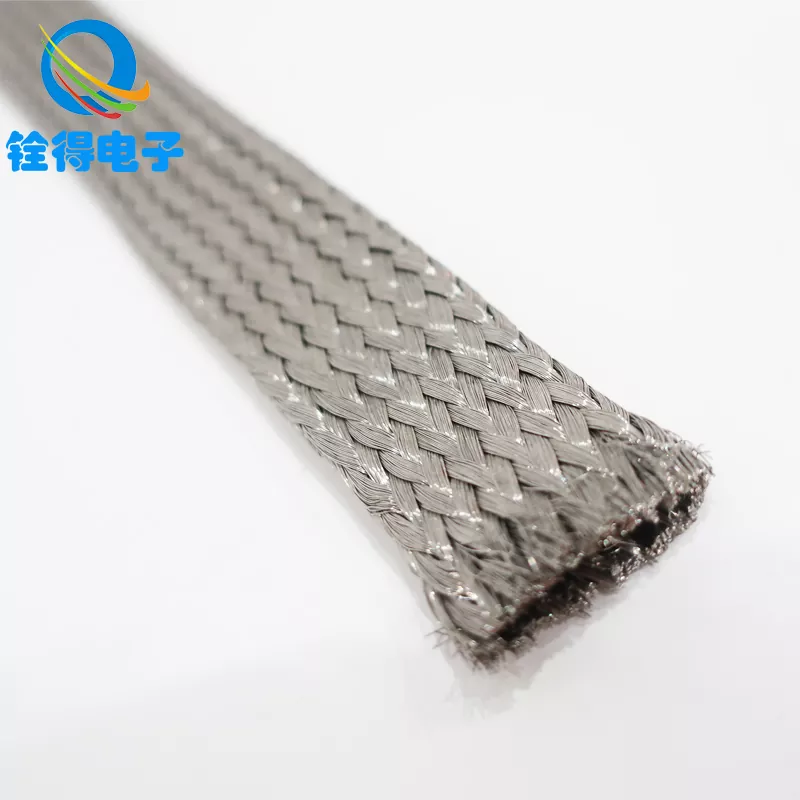

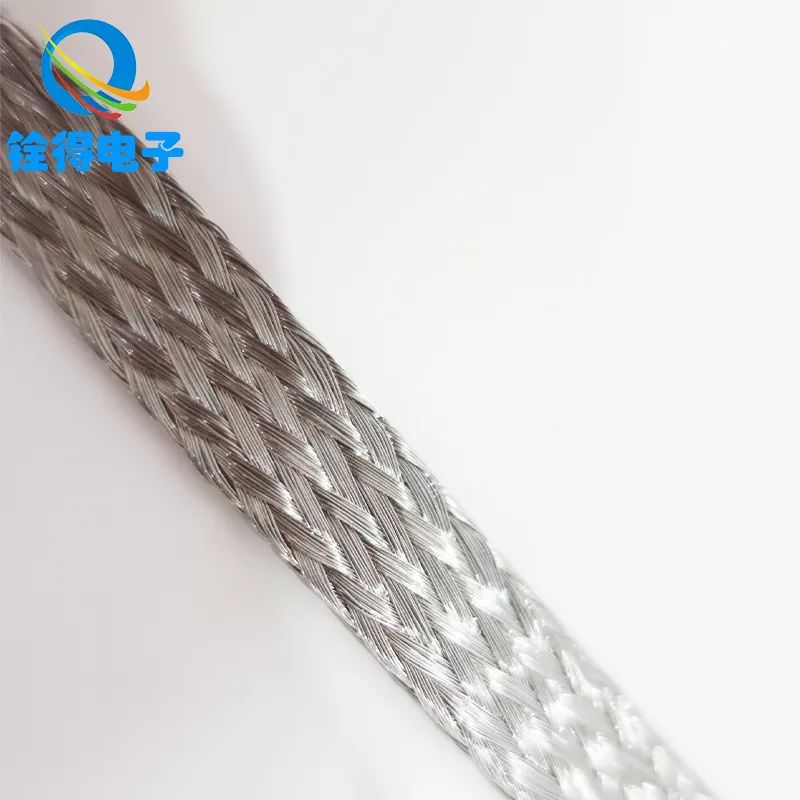

Nickel-Plated Copper Flat Braided Wire

Send Inquiry

Process of nickel-plated copper braided wire: The raw material copper wire must comply with relevant standards, such as GB/T3953-2009 "Electrical Round Copper Wire", and the wire diameter tolerance is controlled within the range of ±0.005mm;

The feed copper wire must be inspected for oxidation and yellowing, and whether there is copper leakage and cracks on the surface. Use a metallographic microscope to observe whether the grain size meets the specified standards;

Use an X-ray fluorescence spectrometer to determine the composition of the coating, and conduct bonding tests and salt spray tests to ensure that the coating quality meets relevant standards;

Nickel-plated copper braided wire is widely used in the electronic and electrical industry as a semiconductor material. Nickel plating can significantly improve its corrosion resistance, weldability and mechanical properties.

Select high-purity copper material as the base material of the braided wire. The conventional wire diameter is 0.1mm\0.15mm\0.2mm, which is the basis for ensuring the quality of the final product; copper has good conductivity and ductility.

The scope of nickel-plated copper flat braided wire is as follows:

Electrical connection and conductive scene

Function: Use the excellent conductivity of copper (conductivity ≥ 97%) to achieve low-resistance conduction, and the nickel layer protects the copper substrate from oxidation and prolongs the service life.

Application range:

1. Grounding system: As equipment grounding belt and lightning protection grounding connection line, due to the soft braided structure, it can adapt to complex installation environments (such as building grounding grid, distribution cabinet grounding);

2. Battery connection: The soft connection between the power battery modules of new energy vehicles can both conduct electricity and buffer vibration. The nickel layer resists electrolyte corrosion (such as lithium salt in lithium battery electrolyte)

3. High-frequency shielding: The electromagnetic shielding net and cable shielding layer of electronic equipment, the braided structure has a good shielding effect on high-frequency signals (such as 5G equipment), and the nickel layer enhances oxidation resistance.

Mechanical connection and buffering scene

Function: The braided structure is soft and bendable (bending radius ≤ 5mm), which can absorb mechanical vibration and thermal expansion and contraction stress, and the nickel layer improves wear resistance.

Application range:

1. Transformer soft connection: connect transformer winding and output terminal, buffer electromagnetic vibration during operation, and avoid hard connection breakage;

2. Automobile engine conduction: grounding braided wire of engine internal wiring harness, resistant to high temperature (nickel melting point 1455℃) and oil corrosion;

3. Precision instrument connection: flexible conductive parts inside electronic instruments, such as grounding wire of vibration sensor, to avoid rigid connection affecting measurement accuracy.