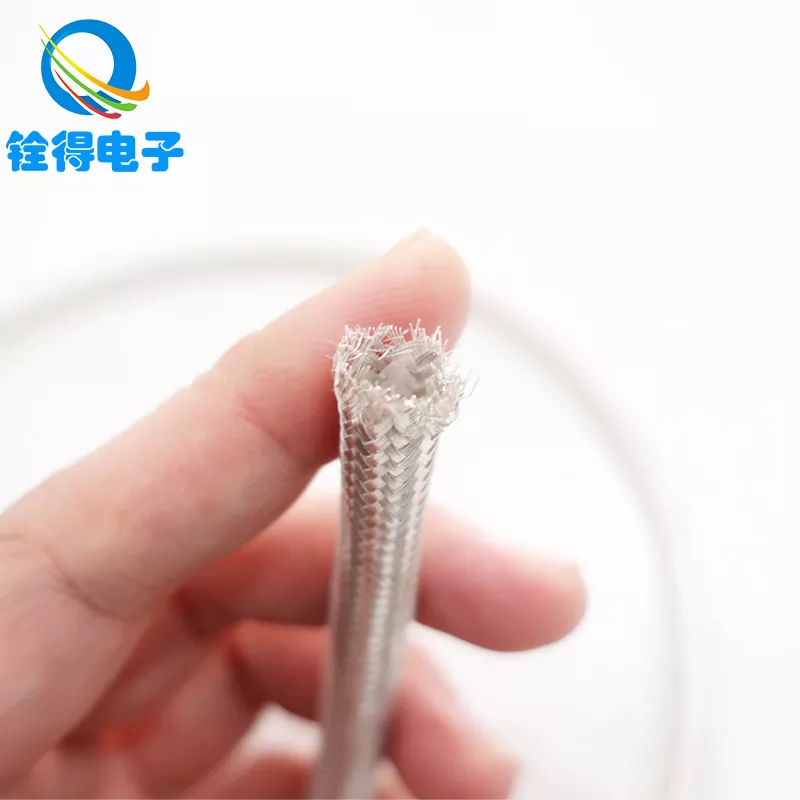

Stainless Steel Corrosion Resistant Mesh Tube

Send Inquiry

The anti-corrosion performance of Stainless Steel Corrosion Resistant Mesh Tube mainly comes from the characteristics of stainless steel itself. Stainless steel contains alloy elements such as chromium. Chromium can form a dense chromium oxide protective film on the surface to prevent corrosive media such as oxygen and moisture from contacting the internal metal, thereby preventing corrosion. This type of mesh pipe is widely used in industries such as chemical, marine, food and beverage, and instrument protection.

1. For example, in the chemical industry, it protects pipeline systems and pipelines that transport corrosive liquids or gases;

2. In some harsh chemical industrial environments and electroplating plants, there are a large number of corrosive chemicals. Cables are wrapped with stainless steel anti-corrosion mesh pipes to avoid being corroded by chemicals, thereby ensuring the safety and stability of power and signal transmission.

3. The line part of precision instruments is very sensitive. In an environment with corrosion risks, stainless steel anti-corrosion mesh pipes can protect the lines, ensure the normal operation of instruments, and ensure the accuracy of measurements.

Stainless steel anti-corrosion mesh pipes have certain tensile strength, flexibility, and wear resistance. For example, in some occasions where a large tensile force is required, the stainless steel flat wire mesh tube is required to have a high tensile strength to prevent breakage; and when used as a bendable protective cover, it requires good flexibility.

Quande Electronics can accurately control costs in terms of price, avoid unnecessary waste and expenses, and make the price more attractive in the market.