Copper Foil Wire Braided Mesh Tube

Send Inquiry

- Electrical properties: copper foil braided network tube has excellent conductivity and electromagnetic shielding performance, can effectively block high-frequency electromagnetic interference, provide good electromagnetic shielding protection for cables, and ensure stable signal transmission.

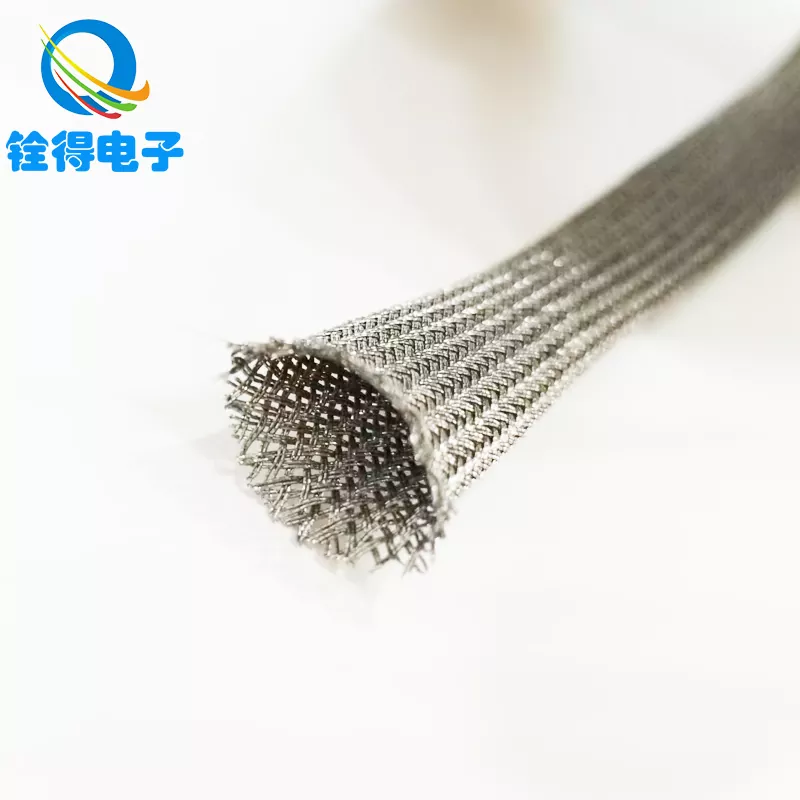

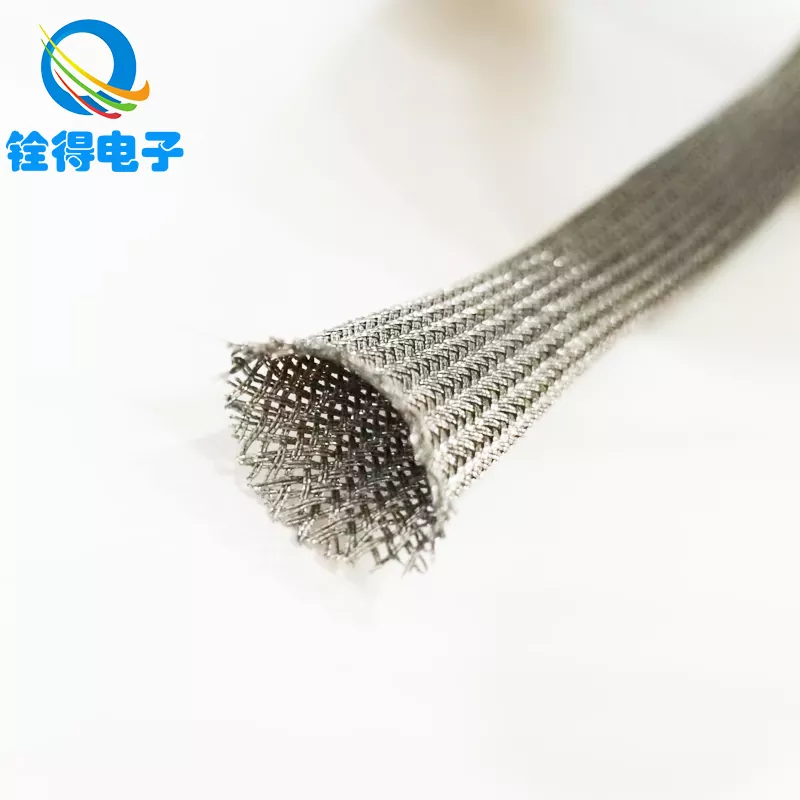

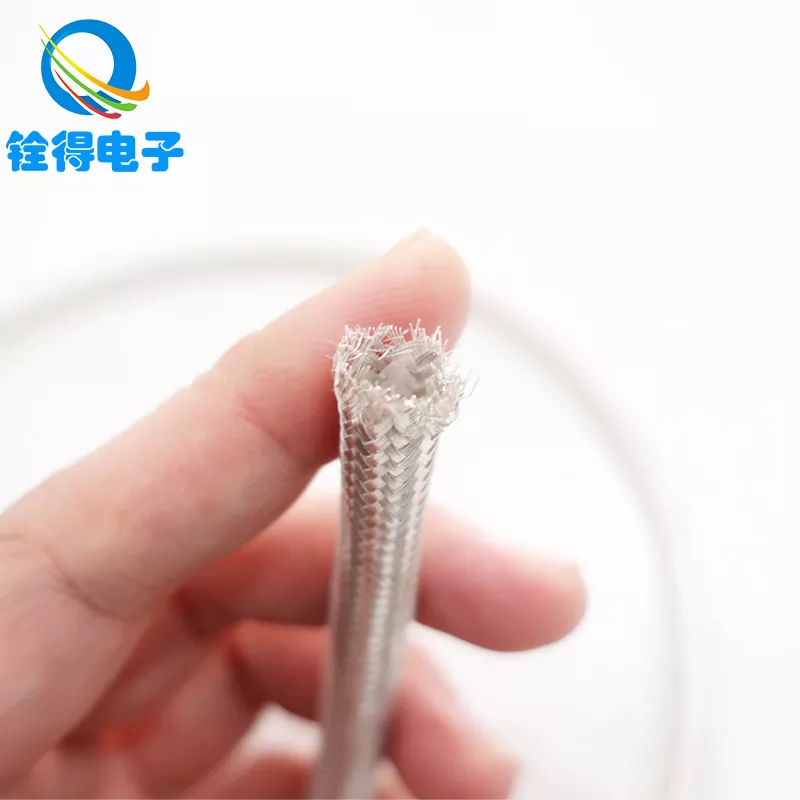

- Mechanical properties: soft texture, easy to bend, retractable, can adapt to cables and equipment of different shapes and sizes; good flexibility, bending strength and tensile strength, can maintain structural stability in complex mechanical movements, and is not easy to break.

- Chemical properties: copper has a certain corrosion resistance, is not easy to oxidize in normal temperature air, and prolongs its service life. Special environments can choose products with surface treatments such as tin plating and nickel plating to enhance its corrosion resistance in harsh environments.

- Thermal properties: It has good thermal conductivity, can quickly dissipate the heat of equipment operation, and has a wide operating temperature range, generally between -60℃ and +200℃.

Application areas of copper foil braided network tube

- Electronic communications: used for internal wiring harnesses and external connecting cables of mobile phones, computers, routers and other devices, such as HDMI cables and USB cables, to prevent signal interference and improve transmission quality.

- Automotive industry: Suitable for battery connection cables, motor control harnesses, etc. of new energy vehicles and fuel vehicles, which can play an electromagnetic shielding and wear-resistant protection role to ensure the stable operation of automotive electronic systems.

- Aerospace: Used for electronic circuit protection of aerospace equipment such as aircraft and satellites, which can ensure line safety and stable signal transmission in harsh environments.

- Medical equipment: Such as magnetic resonance imaging equipment, electron microscopes and other precision medical equipment, it can prevent electromagnetic interference, ensure the normal operation of equipment and the accuracy of test results.

- Power system: In power equipment such as transformers, switch cabinets, generators, etc., it is used for busbar connection, grounding, etc., to improve conductivity and compensate for equipment installation errors.

- Communication system: In 5G base stations, optical fiber communications and other fields, it is used to protect communication cables and improve the stability and reliability of signal transmission.

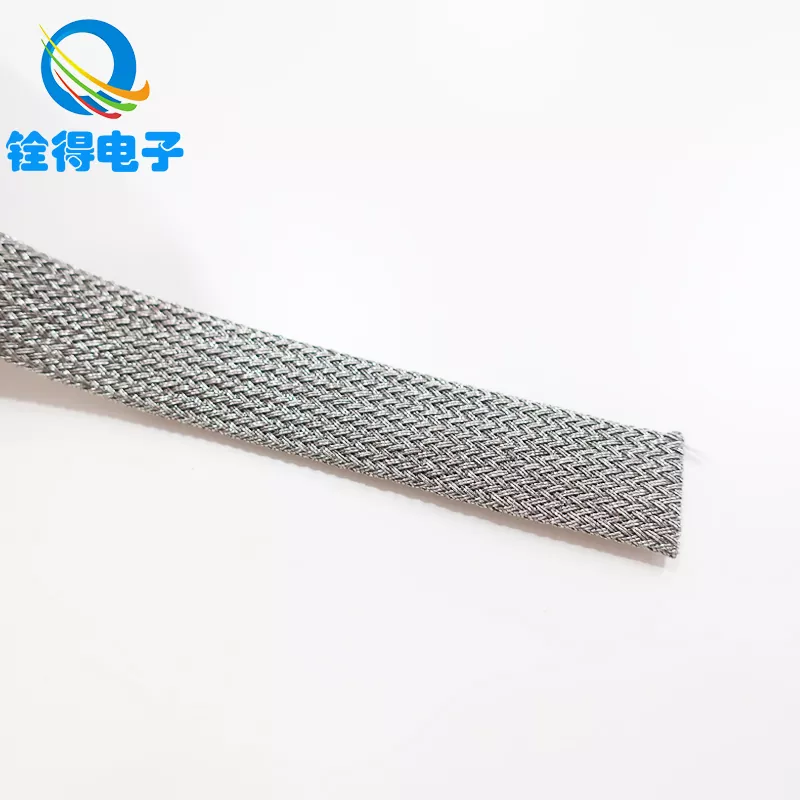

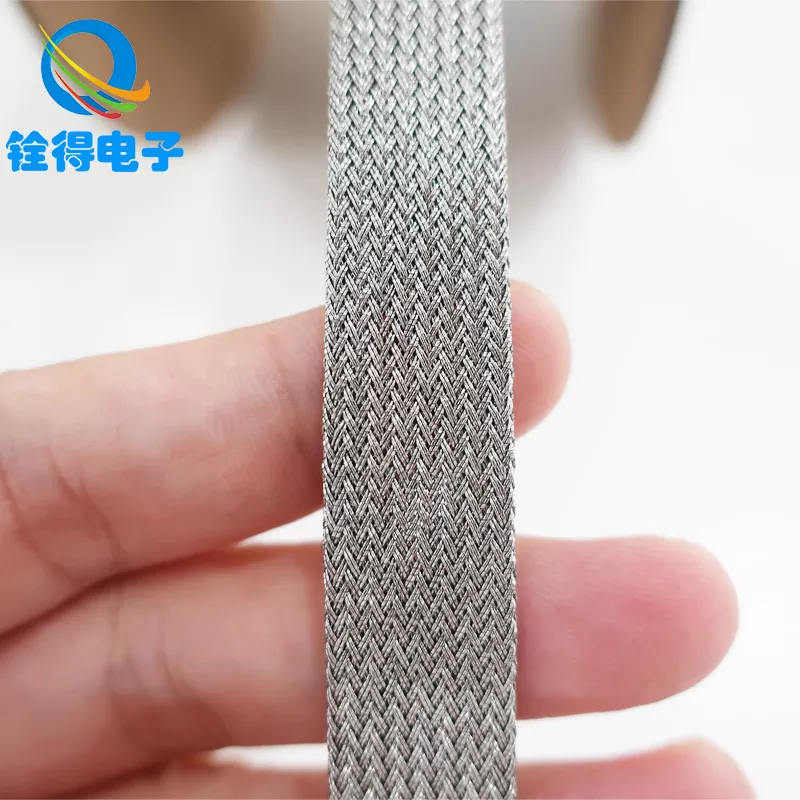

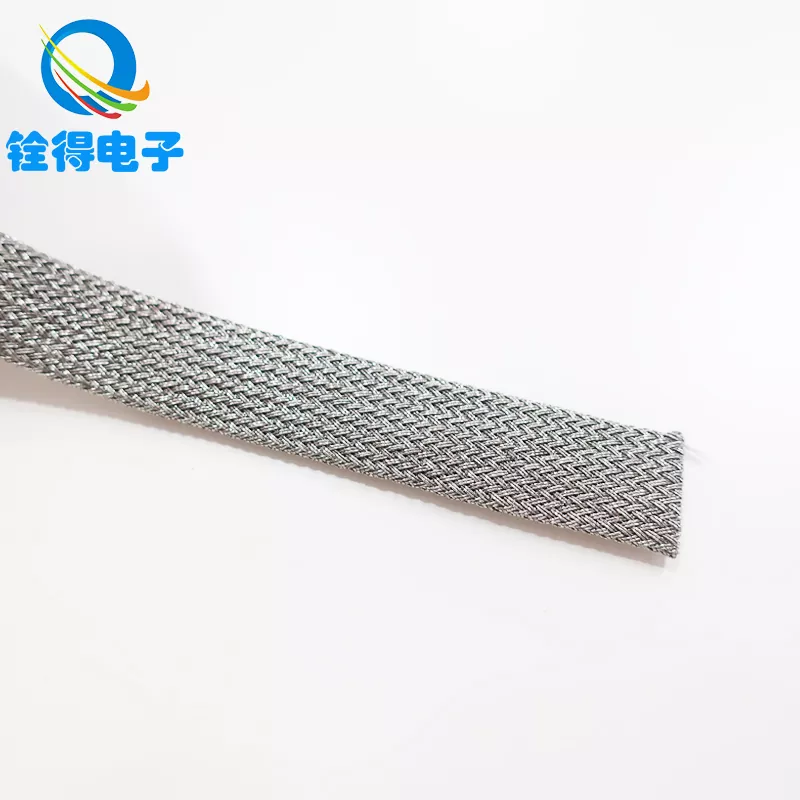

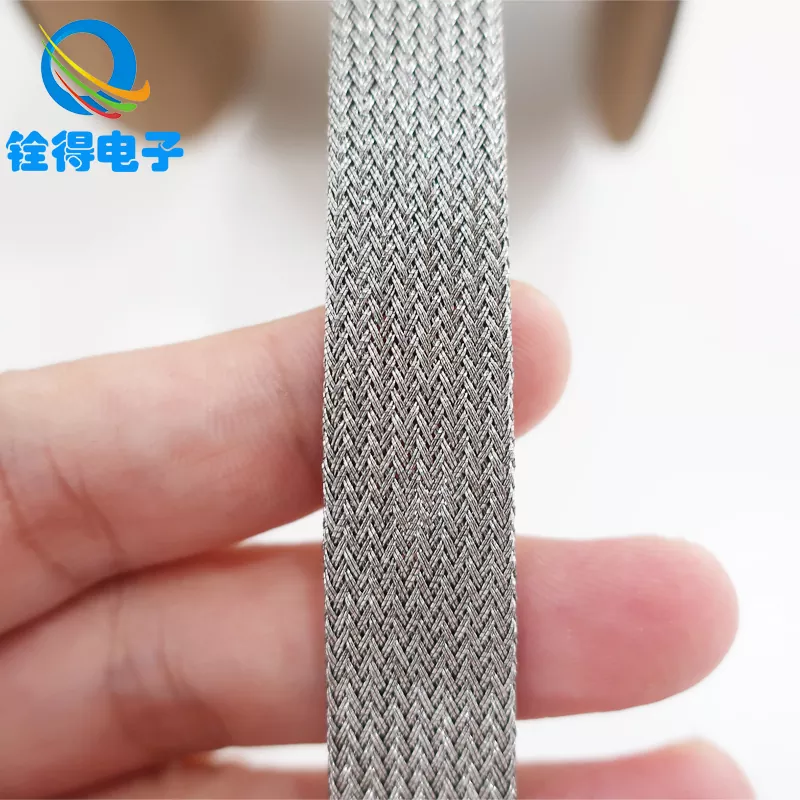

- Structure: The copper foil wire braided mesh tube is woven into a tube through a twill cross-weaving process to form a tight mesh structure; the weaving density, aperture size, number of layers, etc. can be adjusted according to needs. Common weaving methods include plain weave, twill, satin, etc.

-Specifications and dimensions

- Width: Generally available between 1mm-50mm, to meet the needs of different cable diameters and usage scenarios.

- Thickness: Usually 0.1mm-5mm, the thickness selection is related to the braiding density and usage requirements.

- Braiding density: Common braiding density is adjustable between 60%-98%. The higher the density, the better the shielding performance and mechanical strength.