Why Is a Tinned Copper Braided Mesh Tube Essential for Reliable Electrical Shielding?

2025-11-27

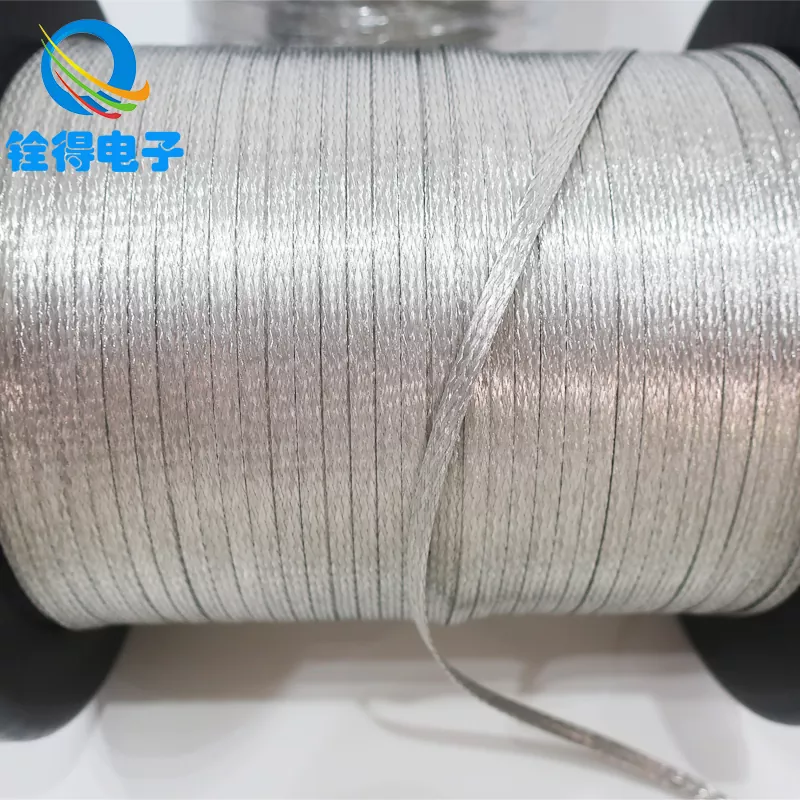

A Tinned Copper Braided Mesh Tube is widely used in electrical, automotive, communication, and industrial applications where superior shielding and grounding performance is required. With its excellent corrosion resistance, high conductivity, and flexible braided structure, it provides stable protection for cables, wiring harnesses, and sensitive electronic components. In my experience working with shielding materials, this product consistently stands out for its durability and easy installation. Dongguan Quande Electronics Co.,Ltd. supplies high-quality options tailored to various engineering needs.

What Are the Key Technical Parameters of a Tinned Copper Braided Mesh Tube?

Below is a clear and professional overview of the core specifications commonly offered by manufacturers like Dongguan Quande Electronics Co.,Ltd.

Product Parameters Table

| Specification | Details |

|---|---|

| Material | Tinned Copper Wire (Usually soft, high-purity copper) |

| Structure | Multi-strand braided mesh tube |

| Wire Diameter | 0.10mm – 0.20mm (customizable) |

| Braid Density | 48–144 carriers depending on shielding level |

| Operating Temperature | -55°C to +200°C |

| Surface Treatment | Hot-dip tinning or electro-tinning |

| Standard Sizes | 3mm – 50mm inner diameter |

| Shielding Efficiency | 60–95% depending on braid tightness |

| Resistance to Corrosion | Excellent (due to tin coating) |

| Application | Cable protection, EMI shielding, grounding straps |

How Does a Tinned Copper Braided Mesh Tube Work in Practical Applications?

A Tinned Copper Braided Mesh Tube serves multiple protective and functional purposes:

Main Functions

-

Electromagnetic Interference (EMI) Shielding: The dense braided structure blocks external interference and stabilizes signal transmission.

-

Anti-Corrosion Performance: The tinned surface significantly slows oxidation, enabling long-term outdoor or marine use.

-

Cable Reinforcement: Prevents wear, bending damage, and mechanical abrasion.

-

Grounding Conduction: Maintains excellent electrical continuity in grounding systems.

Typical Usage Scenarios

-

Automotive wire harness protection

-

Aerospace cable shielding

-

Industrial equipment wiring

-

Audio, video, and high-frequency signal cables

-

Power distribution cabinet grounding

Why Is the Tinned Copper Braided Mesh Tube Important for Long-Term System Stability?

Its importance can be summarized into three core aspects:

-

Improved Service Life: Tin-plating resists rust and oxidation, ensuring consistent conductivity over time.

-

Enhanced Electrical Safety: It stabilizes grounding circuits and prevents electromagnetic interference that may affect device performance.

-

Better Mechanical Protection: The braided design is flexible yet strong, making it ideal for dynamic and high-vibration environments.

These benefits make it a preferred solution in communication engineering, smart home wiring, renewable energy systems, and industrial automation.

What Performance Effects Can You Expect After Using a Tinned Copper Braided Mesh Tube?

After integrating this braided mesh tube into your cable assemblies, you can expect:

Performance Outcomes

-

Reduced EMI Noise: Significantly cleaner signal output.

-

Extended Cable Lifespan: Protection from friction, bending, and heat.

-

Stable Conductivity: Even under long-term load and temperature variations.

-

Improved System Reliability: Especially in precision electronics.

These results make the product a dependable choice for engineers seeking long-term electrical stability.

FAQ About Tinned Copper Braided Mesh Tube

1. What makes a Tinned Copper Braided Mesh Tube better than a standard copper braid?

The tin coating protects the copper from oxidation, increasing its lifespan and maintaining stable conductivity—especially in humid, outdoor, or high-salinity environments.

2. How do I choose the right size of Tinned Copper Braided Mesh Tube?

Measure the outer diameter of your cable and choose a mesh tube with an inner diameter slightly larger (usually 10–20% expansion margin). This ensures smooth installation and full coverage.

3. Can a Tinned Copper Braided Mesh Tube improve electromagnetic shielding performance?

Yes. The dense braided pattern delivers strong EMI protection, significantly reducing noise and enhancing signal clarity in data, audio, and high-frequency applications.

4. Is a Tinned Copper Braided Mesh Tube suitable for high-temperature environments?

Most tubes operate from -55°C to +200°C, making them ideal for automotive engines, industrial machines, and other heat-exposed locations.

Contact Information

If you need customized specifications, bulk supply, or technical guidance, please feel free to contact Dongguan Quande Electronics Co.,Ltd. Our engineering team provides solutions designed to meet global industry standards and performance expectations.