Why Copper Braid Is the Quiet Fix for Unreliable Grounding?

2025-12-30

Abstract

Copper braid looks simple—just strands woven into a flexible ribbon—but it shows up in places where “simple” problems turn expensive fast: overheating busbar links, grounding straps that crack under vibration, shielding paths that go intermittent, and battery or inverter joints that loosen after a few months. This article breaks down what copper braid actually does, which common failures it prevents, and how to choose the right braid for your current, environment, and mechanical stress. You’ll also get installation tips that reduce callbacks, a comparison against cable lugs and rigid straps, and an FAQ that answers the questions most teams only ask after something goes wrong.

Contents

- What Is Copper Braid and Where Does It Fit?

- Customer Pain Points Copper Braid Solves

- Choosing the Right Copper Braid

- Sizing and Performance

- Installation Tips That Prevent Callbacks

- Common Mistakes and How to Avoid Them

- Copper Braid vs. Alternatives

- Quality and Traceability

- Applications by Industry

- FAQ

- Wrap-Up

Outline

- Define copper braid in plain language and explain why flexibility is the whole point.

- Map braid benefits to real pain points: heat, vibration, corrosion, and electrical noise.

- Provide a selection checklist: plating, weave, size, termination method, and environment.

- Share installation habits that keep resistance low and service life high.

- Compare copper braid with cables, rigid bars, and braided sleeving.

- Close with a buyer-friendly quality checklist and a clear next step.

01What Is Copper Braid and Where Does It Fit?

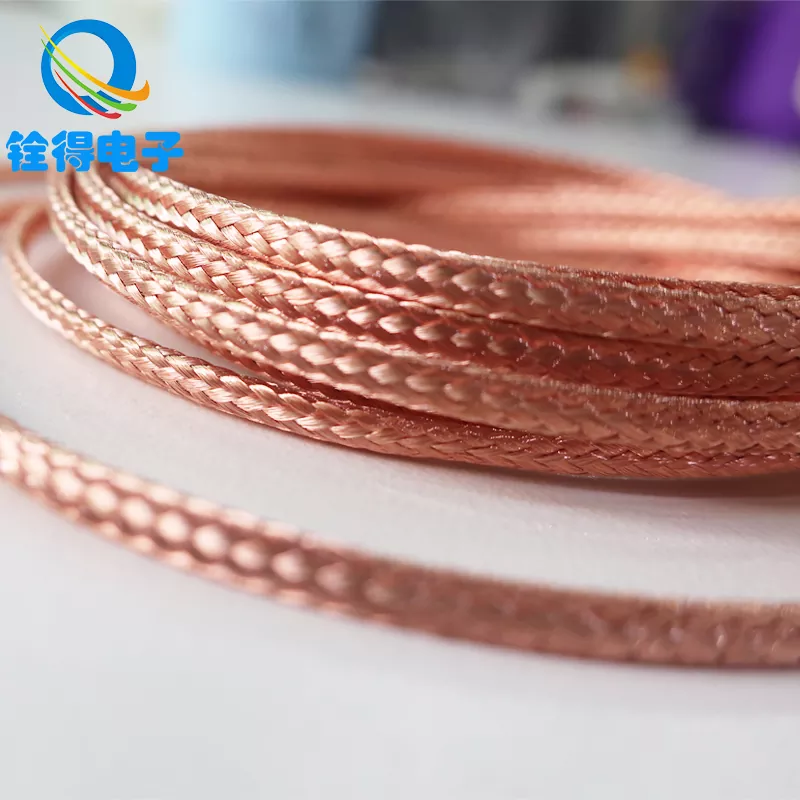

Copper braid is a woven conductor made from many fine copper strands. Instead of acting like a stiff rod, it behaves like a flexible strap: it bends easily, absorbs movement, and spreads electrical current across a wide, low-profile path.

That flexibility is not a “nice-to-have.” It’s the reason copper braid is used in grounding, bonding, and high-current links where vibration, thermal expansion, door/hinge motion, or repeated service access would fatigue a rigid connector. In other words: if your connection point moves even a little, copper braid can keep electrical continuity without cracking, loosening, or concentrating stress on one bolt.

Rule of thumb: If your current path needs to survive movement, copper braid is often the simplest way to make that path both conductive and durable.

02Customer Pain Points Copper Braid Solves

1) “Our grounding strap keeps failing after vibration.”

Braids distribute bending across thousands of micro-strands. That means the strap can flex repeatedly without a single hard “hinge point” that cracks. In vehicles, generators, switchgear doors, and rotating equipment, this is often the difference between a strap that lasts weeks and one that lasts years.

2) “We see hot spots at the joint, but the torque is correct.”

Heat usually comes from resistance, and resistance often comes from poor surface contact, oxidation, or a connector that doesn’t sit flat under load. Copper braid can reduce heat by providing a broad contact area and by tolerating slight misalignment without “springing” away from the mating surface.

3) “Signal noise and interference are killing our stability.”

Ground and bonding paths affect noise performance more than most teams want to admit. A stable, low-impedance bond can reduce floating potentials and help shielding do its job. Braided straps are commonly used to bond enclosures, doors, racks, and panels so the shield path stays continuous over time.

4) “Corrosion is making our connections unpredictable.”

In humid or industrial environments, bare copper can oxidize. Plated options (commonly tinned copper) can improve corrosion resistance and solderability, especially when maintenance intervals are long or the equipment is outdoors.

03Choosing the Right Copper Braid

Most buying mistakes happen because people select copper braid like it’s a generic commodity. It isn’t. The “right” braid is the one that matches your electrical demand and your mechanical reality.

Use this selection checklist before you request a quote:

- Current and duty cycle: continuous vs. short bursts, and how often peaks occur.

- Temperature rise limits: what’s acceptable near insulation, plastics, or sensitive sensors.

- Environment: indoor clean, humid, salty, oily, chemical, or outdoor UV exposure.

- Movement profile: constant vibration, occasional flex, hinge motion, or thermal expansion only.

- Termination method: crimped lugs, welded ends, pressed palms, or soldered connections.

- Mounting geometry: bolt size, spacing, bend radius, and clearance.

- Material pairing: copper-to-aluminum or copper-to-steel interfaces often need extra attention.

04Sizing and Performance

People love asking for a single “amp rating,” but real performance depends on several factors: braid cross-sectional area, strand count, weave tightness, airflow, mounting pressure, and temperature limits around the connector. That’s why two braids that look similar can behave very differently in the field.

What actually matters when sizing copper braid:

- Cross-sectional area: more copper usually means lower resistance and less heat.

- Contact quality at terminations: a great braid with a bad end connection is still a bad assembly.

- Length: longer straps add resistance; keep runs as short as practical without forcing tight bends.

- Flex life: for moving joints, prioritize a construction that tolerates repeated bending.

- Surface condition: plating and cleanliness influence long-term stability.

| Decision Point | Typical Options | When to Choose It | Common Pitfall |

|---|---|---|---|

| Surface finish | Bare copper / Tinned copper | Use tinned where humidity, salt fog, or soldering is involved | Assuming bare copper will stay low-resistance outdoors |

| Form factor | Flat braid / Round braid | Flat for bonding straps and low profile; round where routing is tight | Choosing round for a door bond and creating a stiff hinge point |

| Weave density | Loose / Medium / Tight | Looser can flex better; tighter can hold shape and reduce snagging | Overly tight braid in high-vibration joints → fatigue at ends |

| Termination style | Crimp / Weld / Pressed palm | Weld/pressed palms for stable, low-resistance ends in demanding duty | Relying on “hand-soldered” ends for high-current industrial links |

05Installation Tips That Prevent Callbacks

Many “braid failures” are really installation failures. Here are the habits that keep copper braid working the way you expected.

- Prepare the mating surface: remove paint, oxidation, and contamination where the strap lands. Clean metal-to-metal contact is the baseline.

- Use proper hardware stacks: flat washer for coverage, spring washer where needed, and avoid soft hardware that relaxes under heat.

- Respect bend radius: don’t kink the strap near the termination. If it must bend, let it do so gradually.

- Route for movement: if a door swings, allow a smooth loop rather than a tight arc that concentrates stress.

- Control galvanic interfaces: if bonding copper braid to aluminum, consider compatible plating, surface treatment, or barrier solutions.

- Verify after thermal cycling: in high-current systems, re-check a sample after heat-up and cool-down to confirm stability.

06Common Mistakes and How to Avoid Them

Mistake: Buying “the cheapest braid” and assuming all braids are the same.

Fix: Specify construction, plating, termination method, and a basic inspection standard for every batch.

Mistake: Over-shortening the strap so it’s under tension.

Fix: Give it enough length to flex naturally. A relaxed strap lives longer and stays more stable.

Mistake: Ignoring the end connection.

Fix: Treat terminations as part of the product. The “end” is often where resistance and heat begin.

Mistake: Installing onto painted or dirty surfaces.

Fix: If the surface isn’t conductive, the braid can’t do magic. Clean contact is non-negotiable.

07Copper Braid vs. Alternatives

Copper braid isn’t always the right answer, but it’s often the most forgiving one.

| Option | Strength | Weakness | Best Use |

|---|---|---|---|

| Copper braid strap | Handles movement, broad contact, reliable bonding | Needs good termination and clean surfaces | Doors, panels, vibration zones, flexible grounding |

| Standard cable with lugs | Easy sourcing, familiar installation | Can fatigue near lug; bulkier routing; less “flat” contact | Static connections with moderate movement |

| Rigid copper bar/strap | Very low resistance, stable geometry | Does not tolerate vibration or repeated flex | Fixed bus connections, stable enclosures |

| Shielding braid sleeve | Great for cable shielding coverage | Not a robust power/ground strap by itself | EMI shielding on cables, not bonding straps |

08Quality and Traceability

If copper braid is going into equipment that can’t afford downtime, treat supplier choice like a reliability decision, not just a price decision. Look for consistency: stable weave, controlled materials, and predictable terminations.

At Dongguan Quande Electronics Co., Ltd., teams typically support copper braid applications across grounding, bonding, and conductive interconnect needs, with attention to practical details buyers care about: repeatable construction, finish options suited to environment, and assemblies that fit real installation constraints.

Questions worth asking any supplier:

- Can you provide braid construction details (strand count, braid style, nominal cross-section)?

- What plating/finish options are available for corrosion resistance?

- How are terminations made, and how is end quality inspected?

- What batch identification or traceability is available if a field issue appears?

- Can you help recommend a strap geometry for a door swing, vibration zone, or thermal expansion joint?

09Applications by Industry

Power and energy

- Battery racks and inverter grounding

- Switchgear door bonding and panel grounding

- High-current flexible links where thermal cycling is frequent

Industrial automation

- Machine enclosures and cabinet bonds

- Robotics and moving assemblies

- Ground paths for drives and controls sensitive to noise

Transportation

- Vehicle chassis grounding straps

- Engine-to-frame bonds that survive vibration

- Rail and marine bonding points in harsh environments

Telecom and electronics

- Rack bonding and enclosure continuity

- Shield grounding paths for stable performance

- Serviceable connections that don’t degrade after repeated access

10FAQ

What’s the difference between bare and tinned copper braid?

Bare copper offers excellent conductivity, but it can oxidize more readily in humid or corrosive environments. Tinned copper braid adds a protective layer that typically improves corrosion resistance and makes soldering easier in many assemblies.

Does copper braid reduce electrical noise?

It can help when noise is related to poor bonding or inconsistent grounding paths. A stable, low-impedance bond supports enclosure continuity and can reduce floating potentials that contribute to interference. It’s not a magic filter, but it’s often a key piece of a clean grounding strategy.

Why does my strap run hot even when the braid looks thick?

Heat often starts at the ends. Poor surface prep, oxidation, loose hardware, or low-quality terminations can add enough resistance to create hot spots. Verify metal-to-metal contact, termination integrity, and installation torque strategy—then review strap length and routing.

How long should a copper braid grounding strap last?

Service life depends on movement severity, environment, and installation quality. In gentle conditions, it can last years. In high-vibration or corrosive duty, correct plating, proper routing, and robust terminations become the difference between “short-lived consumable” and “set-and-forget.”

Can copper braid replace a rigid busbar link?

Sometimes. If the goal is flexibility (thermal expansion, vibration, service access), braid is a strong candidate. If the connection is fully static and you need maximum rigidity, a busbar may be more appropriate. Many systems use both: busbar for fixed runs, braid for movement points.

11Wrap-Up

The best copper braid is the one you never have to think about again: it runs cool, stays continuous through vibration, and keeps your grounding and bonding stable even after months of thermal cycling and service access. If you’re dealing with hot joints, intermittent continuity, or noisy equipment that “should be fine,” copper braid is often the cleanest way to remove the mechanical stress from the electrical problem.

If you want help selecting a copper braid construction, termination style, or strap geometry that matches your real operating conditions, reach out to Dongguan Quande Electronics Co., Ltd. and contact us with your current, environment, and mounting details—your future self will thank you.