Why Copper Braided Wires Matter More Than You Think?

2025-12-25

Abstract

Copper Braided Wires look simple—many tiny strands woven into a flat or tubular braid—but they sit at the intersection of electrical performance and mechanical reality. If you’ve ever seen a grounding strap snap after months of vibration, watched a cabinet run hot at the bond point, or chased intermittent EMI issues that “disappear” during inspection, the root cause often lives in the braid choice, termination method, and surface contact quality.

In this guide, you’ll learn what makes braided copper different from solid conductors, how to match braid construction to your use case, what to request in procurement (so you’re not guessing), and how to avoid the most common installation mistakes that turn a good braid into a bad connection.

Table of Contents

- What problems do Copper Braided Wires solve?

- What are Copper Braided Wires and how are they built?

- Where should you use them (and where you shouldn’t)?

- How to select the right braid

- Comparison table for common braid options

- Quality checks and documentation buyers should ask for

- Installation best practices that prevent failures

- Working with Dongguan Quande Electronics Co., Ltd.

- FAQ

Outline

- Translate real-world pain points into braid requirements

- Understand braid structure and why it behaves differently than solid wire

- Choose plating, geometry, and termination based on environment and motion

- Use a simple spec checklist to reduce supplier back-and-forth

- Install correctly to keep resistance low and reliability high

What problems do Copper Braided Wires solve?

Most buyers don’t start by thinking “I need Copper Braided Wires.” They start with a problem:

- Vibration and movement: Solid conductors fatigue. Braids flex and distribute strain across many strands.

- Grounding and bonding reliability: A braid can create a low-impedance path when installed and terminated properly.

- Hot spots at connection points: Poor contact area, incorrect lug/crimp, or undersized braid can concentrate heat.

- EMI and noise issues: In certain grounding/bonding and shielding contexts, braids help manage high-frequency interference paths.

- Corrosive or humid environments: The wrong surface finish can oxidize, increasing resistance and causing intermittent faults.

- Procurement confusion: “Braid width” alone doesn’t define performance; construction and termination matter just as much.

Buyer reality: When a braid fails, it rarely fails on day one. It fails after cycles—temperature swings, vibration, moisture, torque relaxation—when the “weakest link” shows up (often the termination, not the braid itself).

What are Copper Braided Wires and how are they built?

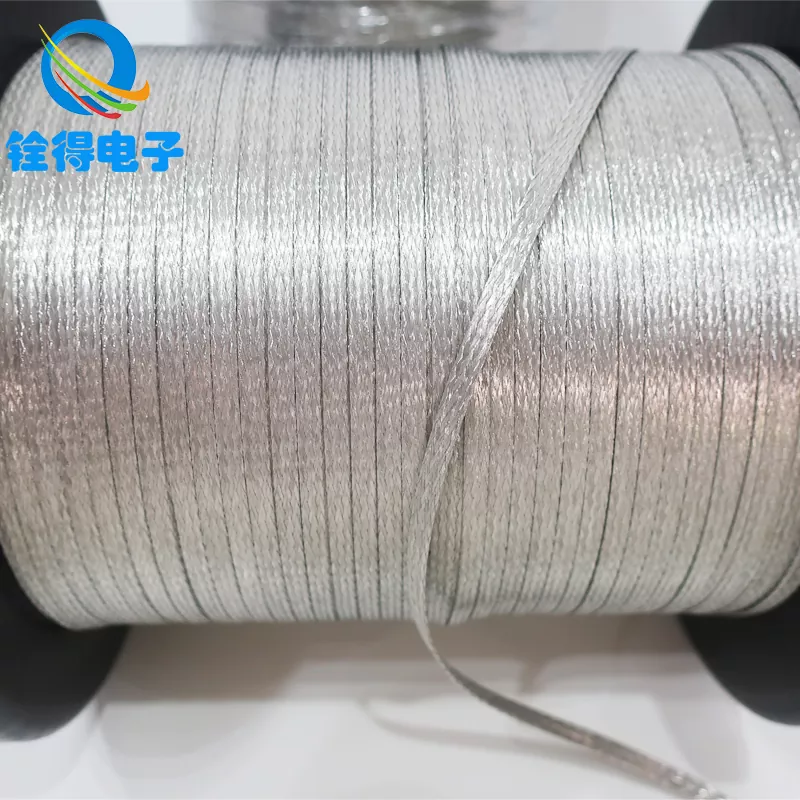

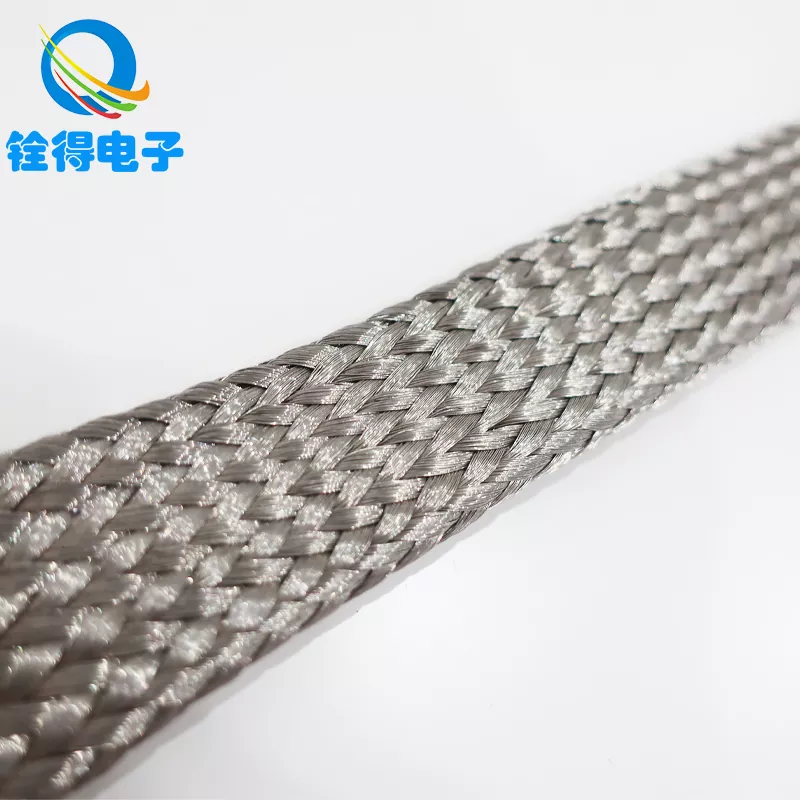

Copper Braided Wires are woven from multiple fine copper strands. That structure creates two practical advantages: flexibility (the braid moves without concentrating stress at one point) and redundancy (many strands share current and load).

But “braid” is not one thing. Here are the core construction variables that change performance:

- Strand diameter and count: Finer strands generally flex better; more strands can share current and improve durability.

- Braid pattern and coverage: Tighter braids often hold shape and contact better; looser braids can be more flexible but may be less robust mechanically.

- Shape: Flat braids are common for grounding straps; tubular braids can be used as sleeves or expandable shielding in certain builds.

- Surface finish: Bare copper vs. plated options (often chosen for corrosion resistance and solderability considerations).

- Termination method: Crimping, welding, soldering, or bolted clamp interfaces—this is where many failures are born.

Tip: If your supplier only asks for “width” and “length,” you’re probably heading toward mismatched expectations. A good vendor will discuss environment, motion, and termination.

Where should you use them (and where you shouldn’t)?

Copper Braided Wires are usually chosen when the connection must carry current (or provide a low-impedance bonding path) while also handling motion or vibration.

| Common use case | Why braid helps | What to watch out for |

|---|---|---|

| Grounding straps in cabinets, panels, and equipment frames | Flexible path between moving or serviceable parts (doors, hinges, removable panels) | Surface prep, bolt torque, anti-oxidation treatment, and contact area |

| Bonding for motors, generators, transformers, and busbar connections | Handles vibration and thermal expansion better than rigid links | Termination quality; avoid sharp bends near lugs |

| Welding, plating, and high-current industrial equipment connections | High flexibility plus robust current-sharing across strands | Heat rise, duty cycle, and mechanical protection |

| EMI management (depending on system design) | Can reduce ground impedance issues in certain layouts | System-level grounding strategy matters more than the braid alone |

Where not to use braid blindly: If your application requires precise, insulated point-to-point wiring with controlled impedance, a braid strap may not be the right “wire” replacement. Braids excel as straps, bonds, and flexible connectors—not as a universal substitute for insulated cable.

How to select the right braid

If you want a procurement-friendly way to spec Copper Braided Wires, use this step-by-step checklist. It turns messy symptoms into clear requirements.

- Define the job: grounding/bonding strap, flexible connector, shielding sleeve, or current-carrying link.

- Estimate electrical demand: current level, duty cycle, and acceptable temperature rise (avoid guessing—use your system data).

- Describe mechanical reality: constant vibration, occasional flex, hinge movement, or thermal expansion cycles.

- Pick shape: flat braid for straps and bonding, tubular braid for sleeving or expandable coverage in certain assemblies.

- Choose surface finish for the environment: humid/salty air, industrial fumes, or indoor clean cabinet.

- Lock termination details: lug type, bolt size, hole spacing, crimp/weld process, and whether ends need tinning or ferrules.

- Plan protection: abrasion sleeves, insulation layers, or strain relief if the braid could rub on sharp edges.

Two questions that prevent 80% of surprises:

- “What is the termination method, and how will it be verified (pull test, resistance check, visual standard)?”

- “What environmental exposure will the braid see, and what finish is recommended to keep resistance stable over time?”

Comparison table for common braid options

Below is a practical comparison you can copy into an RFQ. It focuses on what changes in the real world, not just what looks different in a catalog.

| Option | Best for | Strengths | Trade-offs |

|---|---|---|---|

| Bare copper flat braid | Indoor cabinets, controlled environments, short bonding straps | Great conductivity, cost-effective, simple to terminate | Oxidation risk in harsh humidity; surface may darken and increase contact resistance if not protected |

| Tinned copper flat braid | Humidity, mild corrosion, applications needing better long-term surface stability | Improved corrosion resistance and solderability behavior in many assemblies | Often slightly higher cost; still needs proper contact prep at bolted joints |

| Heavier construction (more strands / tighter weave) | Higher vibration, longer life cycle demands | Better mechanical robustness and strain distribution | May be less pliable; ensure bend radius is respected |

| Tubular braid (sleeve style) | Covering, bundling, or specific shielding-style builds | Expandable, conforms around cables or parts | Not automatically a “ground strap”; needs correct termination strategy |

Pro tip: When comparing suppliers, ask them to state construction details (strand diameter/count, braid coverage, and termination spec). “Equivalent width” is not equivalent performance.

Quality checks and documentation buyers should ask for

If your project is sensitive—power electronics, industrial equipment, rail, EV subsystems, or any safety-critical ground path—treat Copper Braided Wires like a component, not a commodity. Here’s a clean QA request list that works without overwhelming your supplier:

- Incoming material control: copper grade description, plating description (if applicable), and lot traceability

- Electrical verification: resistance/continuity check method and acceptance criteria (per length or per assembly)

- Termination validation: crimp height/width records (if crimped), pull test approach, and visual inspection standard

- Dimensional control: width/thickness tolerance, hole spacing tolerance (if assembled with lugs)

- Compliance documents: CoC/CoA as needed, and environmental compliance statements requested by your market

- Packaging and handling: protection against kinks, contamination, and oxidation during shipping/storage

Installation best practices that prevent failures

Even the best Copper Braided Wires can fail if installed like an afterthought. These are the mistakes that cause intermittent faults, heating, or early mechanical failure:

- Dirty contact surfaces: Paint, oxidation, or oil increases resistance. Prep the metal-to-metal interface.

- Undersized contact area: A tiny washer on a wide braid can create a hot spot. Use appropriate hardware for full contact.

- Sharp bends near terminations: Bending right at the lug concentrates strain—leave a gentle transition and strain relief.

- Loose torque over time: Vibration can relax joints. Use locking methods appropriate to your design and re-check in maintenance cycles.

- Abrasion exposure: If the braid rubs on an edge, add a protective sleeve or reroute it.

- Incorrect path planning: Keep straps short when possible and avoid unnecessary loops that add impedance.

If your failure mode is “it worked during commissioning but fails later,” treat the installation interface (surface prep + torque + hardware + strain relief) as part of the electrical design.

Working with Dongguan Quande Electronics Co., Ltd.

If you’re sourcing Copper Braided Wires for grounding straps, bonding links, or flexible connections, the fastest path to a reliable result is a supplier who speaks both “engineering” and “procurement.” Dongguan Quande Electronics Co., Ltd. positions its braided copper products around practical build needs: configurable dimensions, application-driven braid choices, and assembly options that fit real installation constraints.

When you reach out, you’ll get better recommendations (and fewer revisions) if you share three things up front:

- Your application: ground strap, flexible connector, bonding strap, or sleeve-style braid use

- Your environment: indoor cabinet, humid plant, coastal air, vibration level

- Your termination plan: bolt size/hole spacing, lug type, and whether you need pre-assembled ends

FAQ

Q: Are Copper Braided Wires better than solid wire for grounding?

Often yes for straps and bonds that move or vibrate. The braid’s flexibility helps prevent fatigue and keeps the connection stable—provided the termination and contact surfaces are done correctly.

Q: Should I choose bare copper or tinned copper braid?

Bare copper can be cost-effective in controlled environments. In humid or mildly corrosive settings, a plated finish is commonly chosen to help maintain stable surface behavior over time. The best choice depends on exposure, maintenance cycles, and termination method.

Q: What matters more: braid width or braid construction?

Construction matters at least as much as width. Strand count/diameter, weave tightness, and termination quality often decide durability and real-world resistance stability.

Q: Why do grounding straps heat up?

Heating usually points to resistance at the joint—poor surface prep, small contact area, loose torque, or incorrect hardware. The braid may be fine; the interface is the culprit.

Q: What should I include in an RFQ for Copper Braided Wires?

Include application, length, width/thickness range (or target cross-section), environment, motion/vibration description, termination details (hole size/spacing, lugs), and any required documentation.

Closing thoughts

Buying Copper Braided Wires gets easy once you stop treating them like “just copper” and start treating them like a working interface between electricity and motion. Define the environment, lock the termination, verify quality, and install with respect for contact physics—and you’ll avoid the most expensive kind of failure: the intermittent one.

If you want a faster, cleaner selection process for your next project, share your application details and termination requirements with Dongguan Quande Electronics Co., Ltd.—we’ll help you match the right braid construction to your real operating conditions. Ready to reduce heat, vibration failures, and sourcing uncertainty? contact us and get a quote or technical recommendation tailored to your use case.