What Makes Braided Copper Tube a Reliable Solution for Industrial Applications

2025-11-11

As a member of Quande, a manufacturer deeply rooted in the copper tubing industry, I’ve witnessed firsthand how Braided Copper Tube has become one of the most dependable components in modern industrial systems. From HVAC to automotive and high-voltage power systems, its stability, flexibility, and corrosion resistance make it a go-to choice for engineers who demand performance and reliability. But what exactly makes this product stand out among other tubing solutions? Let me share the insights we’ve gathered from years of manufacturing and customer feedback.

Why Does Braided Copper Tube Offer Better Durability?

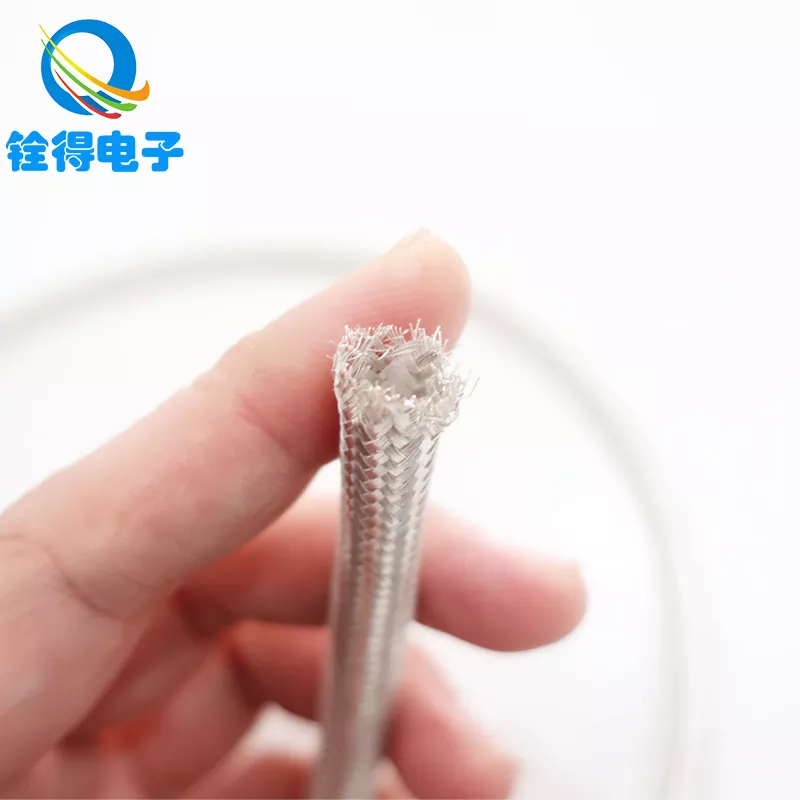

Durability is one of the top reasons our clients choose braided copper over conventional tubing. The braided structure acts as both a shield and a stabilizer — it distributes stress evenly across the tube’s surface, preventing cracks or deformation even under extreme pressure.

In addition, copper’s natural corrosion resistance ensures a long service life, especially in humid or chemical-rich environments. This combination of materials and design results in tubing that performs consistently, even after years of operation.

How Does It Maintain Excellent Flexibility and Pressure Resistance?

Industrial systems often require tubing that can bend or move without leaking or breaking. Our Braided Copper Tubes are designed with multi-layer construction that allows high flexibility while maintaining strong pressure resistance.

Technical Specifications Overview:

| Parameter | Specification | Description |

|---|---|---|

| Material | C11000 Pure Copper | Excellent electrical and thermal conductivity |

| Braid Type | Double-layer Stainless Steel | Enhanced pressure strength and vibration absorption |

| Working Pressure | Up to 25 MPa | Suitable for high-pressure environments |

| Temperature Range | -196°C to 450°C | Wide operating range for industrial use |

| Inner Diameter Range | 6 mm – 50 mm | Customizable for various systems |

| Surface Treatment | Annealed / Tinned / Polished | Options for corrosion protection and conductivity |

This unique combination of structure and material ensures both flexibility and endurance — two qualities that are often difficult to achieve together.

What Are the Common Industrial Applications of Braided Copper Tubes?

Our products are widely applied in multiple sectors, mainly due to their adaptability and performance stability. Some of the key applications include:

-

HVAC systems – for high-efficiency refrigerant transmission

-

Power and energy – for grounding, earthing, and current transfer

-

Automotive industry – for fluid and gas lines in hybrid vehicles

-

Aerospace and shipbuilding – for vibration-resistant connections

-

Chemical and laboratory systems – for transferring reactive fluids safely

These use cases highlight why so many industries prefer braided copper — it’s not just about material quality, but about how the tube performs under real-world conditions.

Why Choose Quande as Your Braided Copper Tube Supplier?

At Quande, we combine precision manufacturing with decades of experience. Our production lines are equipped with advanced annealing, braiding, and surface treatment equipment to guarantee consistent quality. Each tube undergoes strict testing for pressure, leak resistance, and tensile strength before delivery.

Our Core Advantages:

-

20+ years of copper manufacturing expertise

-

Full OEM & ODM customization services

-

ISO9001 certified production system

-

Fast delivery and global logistics support

-

Technical consultation from experienced engineers

How Can You Get the Right Braided Copper Tube for Your Needs?

If you’re looking for a solution that combines durability, flexibility, and superior conductivity, Quande Braided Copper Tube is designed to exceed expectations. Whether you’re upgrading your industrial equipment or developing a new system, we can help you choose the right specifications for optimal performance.

👉 Contact us today to discuss your requirements or request a quotation. Our technical team is ready to support your project from design to delivery — ensuring you get a product that truly fits your application.