Why Do Copper Braided Wires Matter in Modern Electrical Systems?

2025-09-18

In every electrical system, connectivity, conductivity, and flexibility are non-negotiable requirements. As industries push for faster, more reliable, and energy-efficient solutions, the demand for superior conductors has grown. Among the various conductors available, copper braided wires have become indispensable because of their unique combination of conductivity, strength, and adaptability.

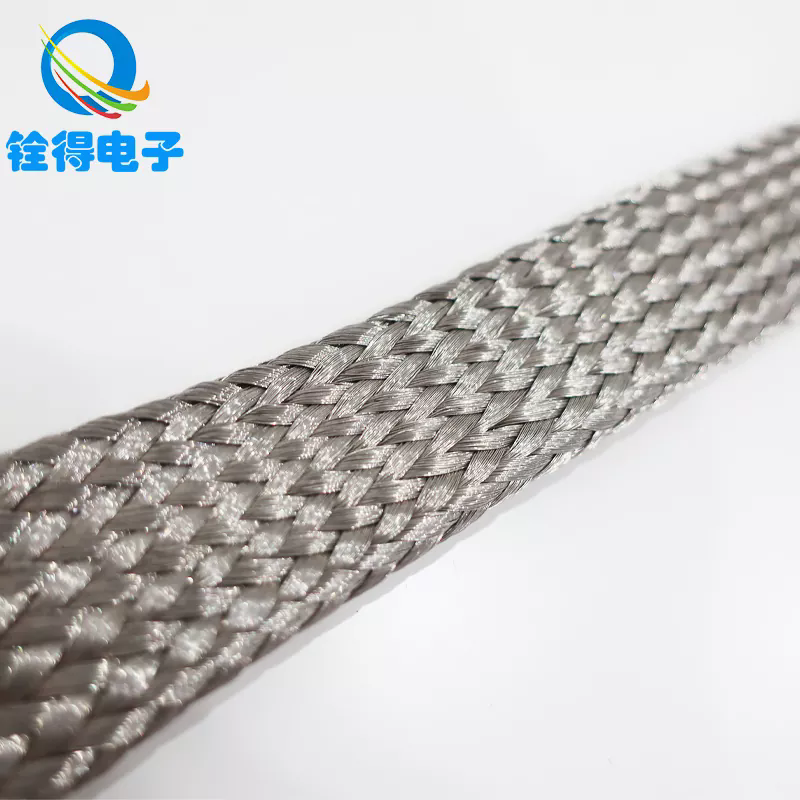

A copper braided wire is essentially a bundle of fine copper strands woven into a braided structure. Unlike rigid solid conductors, this braid offers high flexibility, vibration resistance, and excellent current-carrying capacity. Its ability to dissipate heat and absorb mechanical stress makes it ideal for power distribution, grounding, shielding, and numerous industrial applications.

The use of copper braided wires spans multiple sectors:

-

Electronics: For flexible connections in circuit boards and devices.

-

Automotive: For grounding, battery cables, and connections that endure vibration.

-

Telecommunications: For shielding cables and reducing electromagnetic interference (EMI).

-

Aerospace and Defense: For lightweight, reliable, and durable electrical paths.

-

Renewable Energy: For reliable grounding and power distribution in solar and wind systems.

In short, copper braided wires are not just conductors; they are enablers of safe, efficient, and sustainable power transmission in modern industries.

What Makes Copper Braided Wires Unique Compared to Other Conductors?

The distinctiveness of copper braided wires lies in their structure and material properties. Copper itself is known for its exceptional electrical conductivity, second only to silver. By braiding fine copper strands into a flexible mesh, engineers combine conductivity with durability and mechanical resilience.

Key Characteristics That Set Copper Braided Wires Apart

-

High Flexibility

The braided design allows the wire to bend, twist, and absorb mechanical vibrations without breaking, making it ideal for applications where movement or thermal expansion is expected. -

Excellent Conductivity

With conductivity levels reaching approximately 97% IACS (International Annealed Copper Standard), copper braided wires ensure minimal power loss even under high-current loads. -

Durability and Mechanical Strength

The woven strands distribute mechanical stress evenly, reducing the risk of breakage and extending service life. -

Effective Heat Dissipation

The open braid design promotes airflow, reducing heat buildup and improving performance in high-load applications. -

Corrosion Resistance

Copper braided wires can be tinned or silver-plated for added resistance against oxidation, ensuring long-term reliability. -

Electromagnetic Shielding

The braided structure acts as a Faraday cage, reducing EMI and ensuring signal integrity in sensitive equipment.

Technical Parameters of Copper Braided Wires

| Parameter | Specification Options |

|---|---|

| Material | Pure copper, tinned copper, silver-plated copper |

| Structure | Flat braid, tubular braid, round braid |

| Strand Diameter | 0.05 mm – 0.3 mm |

| Cross-Section Area | 1 mm² – 500 mm² |

| Electrical Conductivity | ~97% IACS |

| Tensile Strength | 200–400 N/mm² depending on design |

| Temperature Range | -40°C to +200°C (with plating or insulation options) |

| Applications | Grounding, power connectors, shielding, flexible bonding |

These parameters can be customized based on industry requirements, ensuring that copper braided wires meet precise operational standards.

What Applications Rely on Copper Braided Wires?

Copper braided wires are widely used across industries because of their adaptability to harsh environments and demanding electrical conditions. Their applications range from small electronic devices to heavy industrial equipment.

Major Applications

-

Grounding Systems

In electrical installations, grounding is essential for safety. Copper braided wires provide low-resistance grounding paths that protect people and equipment from voltage surges or faults. -

Flexible Power Connectors

Used in switchgear, transformers, and battery systems, these wires accommodate mechanical movement while maintaining strong conductivity. -

Automotive Industry

Cars, buses, and trucks use braided copper for battery grounding, anti-vibration connections, and EV charging systems. -

Telecommunications and Data Centers

Copper braided wires shield sensitive communication cables, reducing interference and ensuring reliable data transmission. -

Aerospace and Railways

Lightweight yet strong braided wires help ensure safety and performance in aircraft, trains, and defense systems. -

Renewable Energy

Wind turbines and solar arrays rely on braided grounding wires for stability and lightning protection.

Advantages Across Industries

-

Enhances electrical safety.

-

Reduces downtime by withstanding vibration and mechanical stress.

-

Improves signal quality by reducing electromagnetic interference.

-

Supports sustainable energy systems with long service life.

Common FAQs About Copper Braided Wires

Q1: What is the difference between tinned copper braided wires and bare copper braided wires?

A: Bare copper braided wires offer the highest conductivity but are more prone to oxidation over time. Tinned copper braided wires have a thin coating of tin, which significantly improves corrosion resistance, especially in humid or marine environments, while maintaining excellent conductivity.

Q2: What is the typical lifespan of copper braided wires?

A: The lifespan depends on environmental conditions, current load, and mechanical stress. In standard industrial environments, copper braided wires can last for decades. With protective plating or insulation, their lifespan can be extended further, even in corrosive or high-temperature environments.

What Is the Future of Copper Braided Wires in Global Industries?

As technology advances and industries demand more reliable and sustainable solutions, copper braided wires continue to evolve. Their role in electrification, renewable energy, and digital infrastructure is becoming even more critical.

Trends Shaping the Future

-

Electrification of Transportation: With electric vehicles becoming mainstream, braided copper wires are essential for EV charging infrastructure, battery connections, and onboard grounding.

-

Smart Grids and Renewable Energy: As nations shift to renewable energy, copper braided wires ensure efficient power transmission and grounding in wind and solar systems.

-

Miniaturization of Electronics: Flexible braided wires are increasingly important in compact, high-performance devices where both conductivity and flexibility are required.

-

Enhanced Plating Technologies: Silver-plated copper braided wires offer improved conductivity and oxidation resistance, making them suitable for aerospace and military applications.

-

Sustainability Goals: Recyclable copper braided wires support the circular economy and help industries reduce carbon footprints.

Why Copper Braided Wires Will Remain Indispensable

The combination of flexibility, conductivity, and durability ensures copper braided wires will remain a cornerstone of electrical infrastructure worldwide. Whether in powering vehicles, protecting sensitive electronics, or stabilizing renewable energy systems, their applications will only expand in the future.

At Dongguan Quande Electronics Co., Ltd., we are dedicated to manufacturing high-quality copper braided wires designed for global industries. Our products are engineered with precision, meeting the most stringent standards for conductivity, strength, and environmental performance. With a wide range of customizable options, we deliver solutions that fit the exact needs of our clients across automotive, aerospace, telecommunications, and renewable energy sectors.

For detailed specifications, product inquiries, or customized copper braided wire solutions, contact us today to discover how Dongguan Quande Electronics Co., Ltd. can support your business with reliable and innovative electrical connectivity solutions.