Why Choose Braided Copper Tube for Modern Applications?

2025-09-11

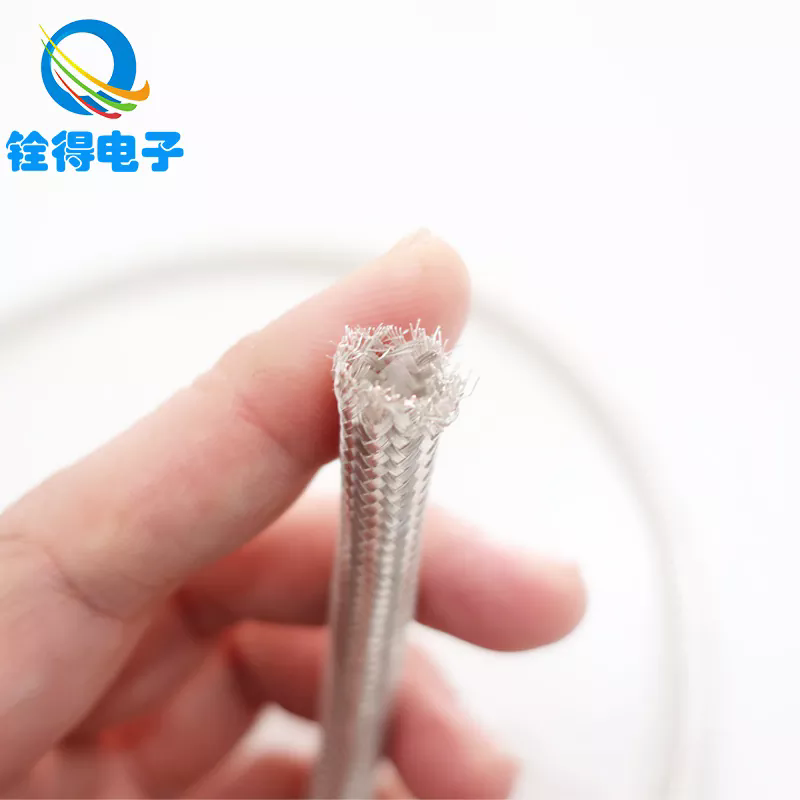

In the modern industrial landscape, the demand for reliable, durable, and efficient piping solutions is higher than ever. Among various materials available, the braided copper tube has emerged as a key component across multiple industries ranging from HVAC, refrigeration, and plumbing to automotive, aerospace, and electrical systems. Its unique construction, which combines the strength of copper tubing with the flexibility and reinforcement of a braided exterior, makes it an indispensable choice for professionals who prioritize safety, efficiency, and longevity.

How Does Braided Copper Tube Outperform Traditional Tubing?

1. Superior Strength and Durability

Unlike ordinary copper tubing, braided copper tube integrates a high-quality braided exterior that reinforces the base copper pipe. This braided design provides resistance to external mechanical stress, vibration, and impact, making it significantly more durable under tough working conditions.

2. Exceptional Flexibility

Flexibility is one of the biggest advantages of braided copper tube. While rigid tubing may crack or deform under bending, braided copper tube can adapt to curved paths and compact installations without compromising flow capacity. This flexibility makes it a preferred choice in complex systems where traditional straight piping cannot fit.

3. Resistance to Pressure and Temperature Fluctuations

Braided copper tubes are engineered to handle both high pressure and extreme temperature ranges. This makes them highly suitable for HVAC systems, refrigeration units, and industrial machinery where fluids or gases operate under fluctuating thermal and pressure conditions.

4. Corrosion Resistance

Copper naturally resists corrosion, but when combined with a braided sheath, the tube achieves enhanced protection against chemical reactions, moisture, and environmental wear. This extends the product’s life cycle, reducing maintenance costs for users.

5. Electrical and Thermal Conductivity

Another distinct advantage of braided copper tube is its high electrical and thermal conductivity. This makes it an excellent choice not only for fluid and gas transportation but also for electrical grounding, shielding, and heat exchange systems.

What Are the Technical Parameters of Braided Copper Tube?

When evaluating any industrial product, technical specifications play a vital role in decision-making. The following table provides an overview of the most common parameters of braided copper tubes:

| Parameter | Specification Range (Typical) | Benefits |

|---|---|---|

| Material | High-grade copper with braided sheath | Ensures durability and conductivity |

| Outer Diameter | 3 mm – 50 mm | Suitable for multiple applications |

| Wall Thickness | 0.5 mm – 2 mm | Provides balance of strength and flexibility |

| Operating Pressure | Up to 150 bar | Withstands high-pressure systems |

| Temperature Range | -50°C to +250°C | Ideal for extreme conditions |

| Bending Radius | As low as 3 × OD | Enables easy installation |

| Corrosion Resistance | High (against moisture & chemicals) | Long-lasting performance |

| Electrical Conductivity | >95% IACS | Efficient for grounding & shielding |

| Surface Finish | Polished / anti-oxidized | Enhanced resistance and aesthetics |

These parameters may vary slightly depending on the specific application or custom requirements, but they represent the general standards adhered to by quality manufacturers.

Why Do Industries Prefer Braided Copper Tube?

1. HVAC and Refrigeration Systems

The flexibility, corrosion resistance, and high-pressure tolerance make braided copper tube ideal for air conditioning and refrigeration. It ensures stable performance even in fluctuating temperatures while reducing the risk of leakage.

2. Plumbing and Water Supply

In plumbing applications, braided copper tubes are valued for their ability to withstand both cold and hot water supply lines. Their resistance to corrosion ensures clean and safe water delivery over long service lives.

3. Automotive and Aerospace Applications

The lightweight yet durable construction of braided copper tubes allows them to handle fuel, hydraulic fluids, and cooling systems in cars, airplanes, and heavy machinery. Their ability to resist vibration is particularly critical in these sectors.

4. Electrical Systems and Grounding

Due to its high conductivity, braided copper tube is widely used for grounding and shielding electrical cables. It ensures reliable current transfer and protection against electromagnetic interference.

5. Industrial Machinery and Oil & Gas Sector

Industries dealing with heavy-duty machinery or chemical processing rely on braided copper tubes because of their ability to withstand harsh chemicals, extreme pressure, and heat.

6. Sustainability and Recycling

Copper is one of the most sustainable materials in the world. Braided copper tubes are 100% recyclable, making them an eco-friendly solution that aligns with modern industries’ green initiatives.

Common Questions About Braided Copper Tube

Q1: What is the main difference between a braided copper tube and a standard copper tube?

A braided copper tube is reinforced with a braided metal sheath, which provides greater durability, flexibility, and resistance to pressure compared to a standard copper tube. This makes it suitable for more demanding applications, especially in industrial, HVAC, and automotive systems.

Q2: How long does a braided copper tube typically last in harsh environments?

When installed correctly, a braided copper tube can last over 20 years, even in high-pressure or corrosive environments. Its longevity is attributed to the natural corrosion resistance of copper and the added protective layer provided by the braid.

Why Braided Copper Tube Is the Future of Piping Solutions

From durability and flexibility to sustainability and performance, braided copper tubes embody the qualities industries demand in modern applications. Their proven ability to operate under high pressure, extreme temperatures, and corrosive environments makes them a versatile solution that outperforms many alternatives.

Whether in HVAC, plumbing, automotive, aerospace, or industrial sectors, braided copper tubes offer unmatched reliability and long-term value. Businesses that invest in this technology not only secure operational efficiency but also reduce long-term costs through fewer replacements and lower maintenance.

At quande, we specialize in providing premium braided copper tubes that meet global quality standards and can be tailored to specific industrial requirements. If you are seeking reliable, durable, and high-performance tubing solutions, we encourage you to contact us today to explore how our products can support your business needs.