What Are the Benefits of Tinned Copper Braided Wires?

2025-02-10

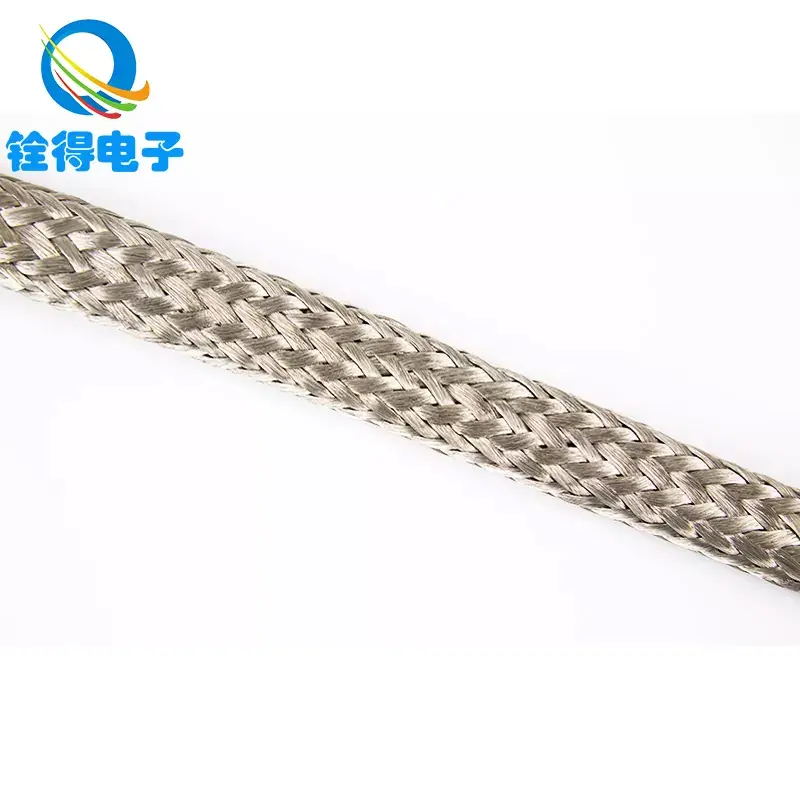

Tinned copper braided wires are widely used in electrical and industrial applications due to their superior durability, conductivity, and resistance to environmental factors. The tin coating on copper enhances its properties, making it more suitable for challenging conditions. In this blog, we’ll explore the key benefits of tinned copper braided wires and why they are a preferred choice in various industries.

1. Corrosion Resistance

One of the biggest advantages of tinned copper is its resistance to oxidation and corrosion. Copper naturally reacts with oxygen over time, leading to oxidation that can degrade performance. The tin coating acts as a protective barrier, extending the lifespan of the wire, especially in humid, salty, or chemically aggressive environments.

2. Enhanced Solderability

Tinned copper offers superior solderability, making it easier to create strong and reliable connections. This reduces the risk of poor conductivity or weak joints in electrical circuits, ensuring stable performance.

3. Improved Durability in Harsh Environments

Tinned copper braided wires perform exceptionally well in extreme conditions, including high humidity, salt exposure, and temperature variations. This makes them ideal for marine, aerospace, and industrial applications where environmental resistance is crucial.

4. Flexibility and Strength

The braided structure of these wires enhances their mechanical strength and flexibility, allowing them to withstand bending and vibrations without breaking. This property is especially beneficial in dynamic applications like automotive and robotics.

5. Superior Electrical Conductivity

While the tin coating adds protection, it does not significantly reduce the excellent electrical conductivity of copper. This ensures efficient power transmission with minimal energy loss.

6. Resistance to Sulfur and Chemical Exposure

Industries that deal with high levels of sulfur or harsh chemicals benefit from tinned copper’s ability to resist tarnishing and degradation. This makes it a top choice for petrochemical plants and power distribution networks.

7. Longevity and Cost-Effectiveness

Although tinned copper braided wires may have a slightly higher upfront cost compared to bare copper, their extended lifespan and reduced maintenance needs make them a cost-effective investment over time.

Tinned copper braided wires offer numerous advantages, from corrosion resistance and enhanced durability to superior conductivity and solderability. Their ability to perform reliably in harsh environments makes them indispensable in industries such as marine, automotive, aerospace, and telecommunications. Choosing tinned copper wires ensures longevity, efficiency, and cost savings in the long run.

Dongguan Quande Electronics Co., Ltd. is one of the traditional large-scale metal braiding suppliers and manufacturers. It is a large copper economic entity integrating R&D, production, sales and services. The company's main products: copper braided belt, tinned copper braided belt, silver-plated copper braided belt, stainless steel braided belt, bare copper braided wire, aluminum-magnesium wire braided belt, copper-clad aluminum braided belt, grounding wire, copper braided soft connection, flange jumper grounding wire, copper brush wire, static connection wire, copper braided network tube, copper stranded wire, tin-absorbing copper braided belt and other production and sales services.Visit our website at www.quandebraid.com to learn more about our products. For inquiries, you can reach us at qiuyonghong105@163.com.