Why Is Braided Copper Tube the Go-To Choice for EMI Shielding and Cable Protection?

Modern electronics are getting smaller, faster, and far more sensitive to noise. That’s great—until a perfectly “working” cable starts causing random resets, unstable signals, or failed compliance tests. If you’re dealing with electromagnetic interference, static discharge, or wiring that keeps getting scuffed and pinched in tight assemblies, Braided Copper Tube is one of the most practical fixes you can implement without redesigning your entire system.

Abstract

This article explains what a Braided Copper Tube does, the common problems it solves (EMI, abrasion, static buildup, and mechanical stress), and how to choose the right construction for your environment. You’ll also find a clear selection checklist, installation best practices, and a comparison table to help you match material options (bare copper, tinned copper, silver-plated copper, and stainless variants) to real-world use cases—so you can avoid overpaying, under-specifying, or installing it in a way that cancels out its benefits.

Table of Contents

- The Pain Points Braided Copper Tube Solves

- What Braided Copper Tube Is and How It Works

- How to Choose the Right Braided Copper Tube

- Material and Build Comparison Table

- Installation and Grounding Best Practices

- Where It’s Commonly Used

- Sourcing and Quality Checks That Actually Matter

- FAQ

- Conclusion

Outline

- Identify whether your issue is EMI, static, abrasion, or tight-bend fatigue

- Understand shielding performance and what “coverage” really means in practice

- Pick the right material finish for your environment (humidity, salt, heat)

- Size it correctly so it fits without choking the cable or leaving gaps

- Install it with proper terminations so shielding doesn’t become “decorative”

- Validate with simple checks: continuity, fit, and grounding integrity

The Pain Points Braided Copper Tube Solves

People usually start searching for Braided Copper Tube when something “mysteriously” goes wrong—especially in assemblies with motors, inverters, switching power supplies, relays, or dense wiring harnesses. Here are the most common pain points it addresses:

- Unstable signals and EMI headaches: Noise coupling can cause data errors, sensor drift, audio buzz, or intermittent communication failures that are painful to debug.

- Failed EMC or compliance tests: You pass function tests, but emissions or susceptibility tests don’t cooperate—often due to shielding gaps or weak grounding.

- Abrasion and mechanical wear: Cables routed through metal edges, moving assemblies, or vibration-heavy systems can wear through insulation over time.

- Static electricity buildup: In dry environments or moving cable carriers, static can accumulate and discharge into sensitive components.

- Tight routing and repeated bending: Some protective sleeves are stiff or bulky. A braided tube adds protection while still bending and flexing with the harness.

The key idea: a braided tube isn’t just “a sleeve.” It’s a functional layer that can reduce interference, protect wiring, and provide a controlled path for unwanted electrical energy—when specified and installed correctly.

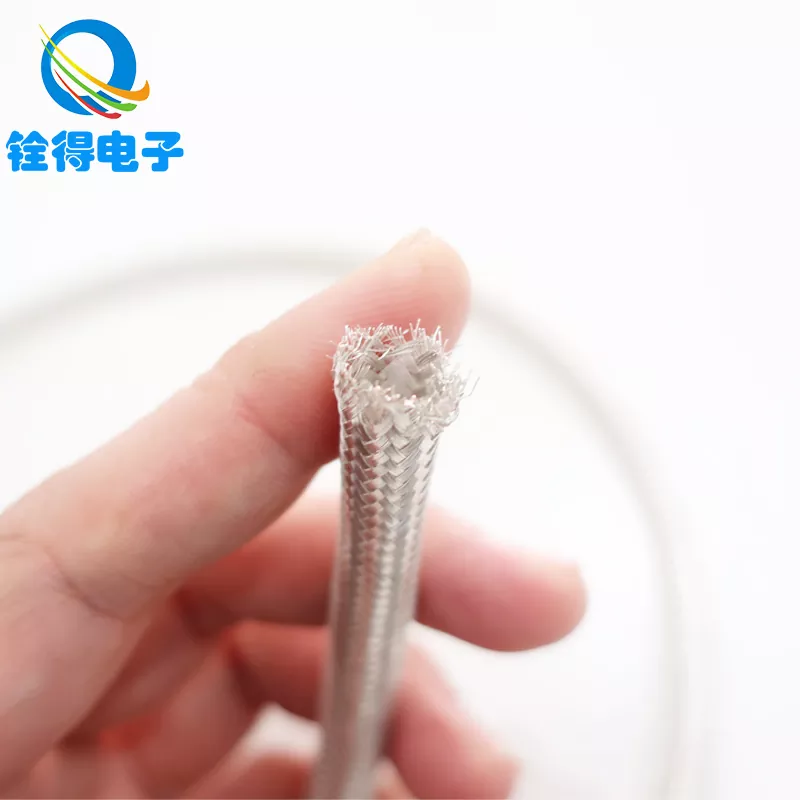

What Braided Copper Tube Is and How It Works

A Braided Copper Tube is a tubular mesh made by braiding conductive wire strands into a flexible sleeve. Because it forms a conductive network around the cable bundle, it can help:

- Attenuate electromagnetic interference by surrounding sensitive conductors with a conductive barrier

- Reduce emissions by containing noise that would otherwise radiate outward

- Provide static discharge capability when connected to a proper ground path

- Improve mechanical protection against abrasion, compression, and scuffing

In real systems, performance depends on details: braid density, coverage, wire diameter, and—most importantly—how you terminate and ground the braid. A high-quality braid with a poor termination can perform worse than an average braid installed correctly.

How to Choose the Right Braided Copper Tube

Choosing a Braided Copper Tube isn’t about picking the “most expensive” option. It’s about matching the tube’s characteristics to your environment and your failure mode. Use this checklist:

- Define the primary goal: EMI shielding, abrasion protection, static discharge, grounding continuity, or a combination?

- Confirm the environment: indoor dry, humid, salt spray, high temperature, chemical exposure, or outdoor enclosure?

- Measure cable bundle size: outer diameter (OD) of the harness, plus expansion needs for connectors.

- Decide on material/finish: bare copper for controlled environments, tinned for corrosion resistance, silver-plated for special conductivity needs, or stainless options for harsh conditions.

- Check braid coverage and density: higher coverage typically improves shielding but can reduce airflow and increase stiffness.

- Plan the termination method: clamp, crimp, solder, or shield termination band—this affects performance more than many people expect.

A practical sizing rule: pick an inner diameter that fits smoothly over the bundle without forcing it. Too tight and you’ll deform the braid (and stress the cable). Too loose and you’ll create gaps, movement, and inconsistent contact.

Material and Build Comparison Table

| Option | Best For | Strengths | Watch Outs |

|---|---|---|---|

| Bare Copper Braid Tube | General indoor electronics, controlled environments | Excellent conductivity, flexible, cost-effective | Oxidation in humid/corrosive settings can raise resistance over time |

| Tinned Copper Braid Tube | Automotive, industrial cabinets, humid environments | Better corrosion resistance, stable performance, easier soldering in many cases | Slightly higher cost than bare copper; confirm finish quality |

| Silver-Plated Copper Braid Tube | Specialized high-performance electrical applications | High conductivity surface, strong electrical performance in demanding scenarios | Higher cost; specify only when your application truly needs it |

| Stainless/Hybrid Mesh Tube | Harsh environments, abrasion-heavy routing, special protection needs | Corrosion resistance, wear resistance, durability | Conductivity and shielding behavior differ from copper—verify requirements |

Installation and Grounding Best Practices

This is where many shielding projects fail—not because the braid is “bad,” but because the installation makes it ineffective. Keep it simple and disciplined:

- Maintain continuous coverage: Avoid big gaps, pulled-open sections, or abrupt diameter transitions that create leakage paths for interference.

- Terminate correctly: Use a clamp or termination band that creates consistent, 360-degree contact around the braid when possible.

- Ground with intent: If you want shielding performance, connect the braid to a stable ground reference using a low-impedance path. Long, thin “pigtails” can reduce effectiveness at higher frequencies.

- Protect the ends: Add heat-shrink or mechanical strain relief to prevent fraying and to reduce sharp-edge damage to the underlying insulation.

- Account for movement: In moving harnesses, allow enough slack so the braid doesn’t become the stress point.

A quick validation habit: after installation, do a continuity check across the braid length and confirm that your termination points have firm mechanical contact. If the braid can twist freely at the end, your “shield” may not be bonded the way you think it is.

Where It’s Commonly Used

You’ll see Braided Copper Tube in any industry that mixes sensitive signals with noisy power electronics or tight wiring constraints. Common scenarios include:

- Computers and data equipment: protecting internal data and power lines from interference and mechanical wear

- Communication systems: minimizing external interference and reducing cross-talk between harnesses

- Automotive electronics: supporting stable operation in complex onboard electromagnetic environments

- Industrial automation: cable protection around PLC control wiring, motor drives, and sensor harnesses

- Medical equipment: improved electromagnetic stability for precision instruments and diagnostic systems

If your system includes switching, rapid transients, or dense harness routing, a braided sleeve can be one of the most cost-effective improvements—especially compared with redesigning boards, changing cable routes, or adding bulky filtering everywhere.

Sourcing and Quality Checks That Actually Matter

Not all braided tubes are equal. Two tubes can look similar at a glance and perform very differently in real assemblies. When evaluating suppliers, focus on tangible indicators:

- Uniform braid structure: consistent weave reduces weak spots and improves repeatability in installation

- Stable dimensions: inner diameter and expansion behavior should be predictable across batches

- Material and finish consistency: plating/finish quality affects corrosion resistance and long-term electrical stability

- Mechanical handling: good braids resist fraying, deforming, and snagging during routing

- Customization support: if your harnesses have unusual diameters, lengths, or termination needs, customization can save time and reduce assembly risk

This is where working with an experienced manufacturer can reduce trial-and-error. For example, Dongguan Quande Electronics Co., Ltd. produces braided copper tube options intended for shielding and cable protection across multiple application environments, and can support different material choices and specifications depending on how you plan to route and terminate the sleeve.

FAQ

Q1: Does braided copper tube work for both shielding and physical protection?

A: Yes. It can help reduce electromagnetic interference while also protecting cables from abrasion and compression. The balance depends on braid density and how the tube is installed.

Q2: Is tinned copper always better than bare copper?

A: Not always. Bare copper performs well in controlled environments and is often more cost-effective. Tinned copper is a smarter choice when humidity, oxidation risk, or long service life in harsher environments matters.

Q3: How do I size braided copper tube for a cable bundle?

A: Measure the outer diameter of the full bundle (including jacket thickness) and select an inner diameter that slides on without forcing. If the bundle has connectors, consider an expandable sleeve or plan installation before termination.

Q4: Why does shielding sometimes “not work” even with a braided sleeve?

A: The most common reason is poor termination or grounding. If the braid isn’t bonded properly (or the grounding path is high impedance), shielding effectiveness can drop dramatically.

Q5: Can braided copper tube help with static electricity?

A: It can, as long as it’s connected to a controlled discharge path. The braid’s conductivity can help dissipate static buildup rather than letting it accumulate and discharge unpredictably.

Conclusion

If you’re fighting EMI, chasing intermittent faults, or trying to protect harnesses in tight, high-stress routing paths, Braided Copper Tube is one of those upgrades that can deliver outsized results—without turning your whole design upside down. The trick is to choose the right material for your environment, size it correctly, and terminate it in a way that preserves continuous shielding and reliable contact.

If you want help selecting the right specification—or you’re trying to solve a stubborn interference or durability issue in a real assembly—Dongguan Quande Electronics Co., Ltd. can support your project with braided copper tube options tailored to your application. Ready to move from “guessing” to a cleaner, more reliable wiring solution? contact us to discuss your requirements and get a practical recommendation.