Why Are Copper Braided Wires Essential for Reliable Electrical Connections?

2025-10-29

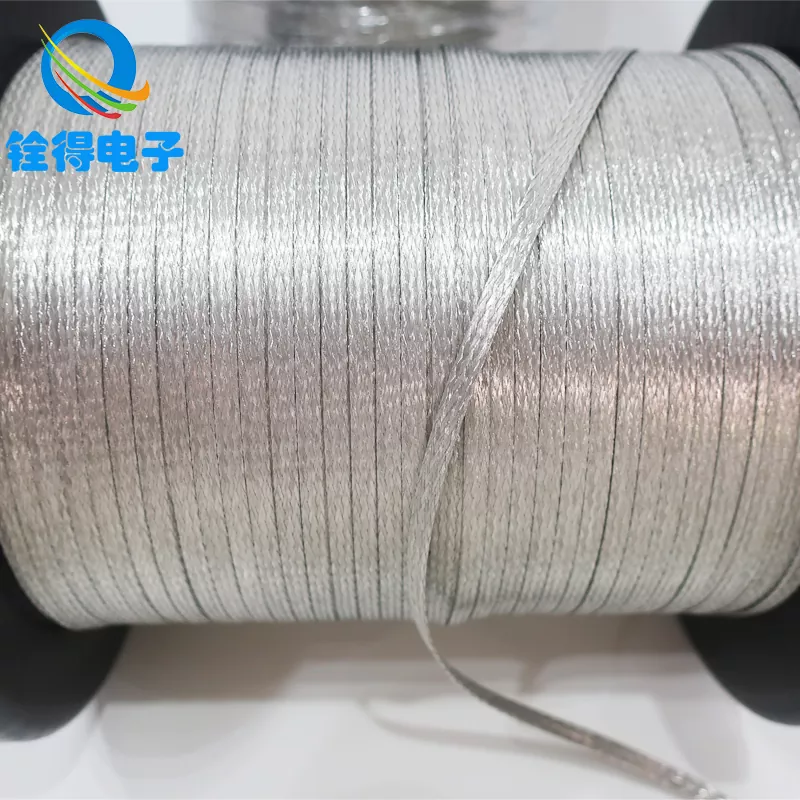

Copper Braided Wires are flexible conductors made from multiple fine strands of copper wire woven together in a braided pattern. This structure allows them to combine excellent conductivity with remarkable mechanical flexibility. They are commonly used in electrical systems where movement, vibration, or thermal expansion occurs—such as in transformers, switchgear, electric vehicles, grounding systems, and flexible connectors.

In my experience working with electrical components, I've found that Copper Braided Wires play an irreplaceable role in ensuring stability and safety. But what makes them so reliable? Let's explore their characteristics, performance, and benefits in detail.

How Do Copper Braided Wires Function in Electrical Applications?

The primary role of Copper Braided Wires is to conduct electricity efficiently while allowing flexibility. Unlike solid copper bars or rigid cables, braided wires can bend, twist, and absorb vibrations without breaking. This makes them ideal for dynamic environments or connections that require frequent movement.

They are also used as grounding straps, helping to safely dissipate fault currents and protect electrical equipment. The fine copper strands provide a large surface area, improving conductivity and minimizing electrical resistance.

Furthermore, their woven structure allows excellent heat dissipation, which reduces the risk of overheating during continuous operation.

What Are the Key Specifications and Parameters of Copper Braided Wires?

Dongguan Quande Electronics Co., Ltd. provides a wide range of Copper Braided Wires designed for industrial and commercial applications. Below is a summary of our standard product specifications:

| Parameter | Specification | Description |

|---|---|---|

| Material | Tinned or bare copper | Offers excellent conductivity and corrosion resistance |

| Wire Diameter | 0.05mm – 0.30mm | Fine strands for enhanced flexibility |

| Cross-sectional Area | 1mm² – 500mm² | Customizable to application needs |

| Braid Structure | Flat, round, or tubular | Suitable for various connection designs |

| Tensile Strength | 200 – 400 N/mm² | Provides high mechanical stability |

| Operating Temperature | -50°C to +200°C | Ensures reliable performance under extreme conditions |

| Resistance (Ω/km) | < 0.02 | Low electrical resistance for high efficiency |

| Finish | Tin-plated / Nickel-plated / Bare | Options for enhanced corrosion resistance |

| Standards Compliance | IEC / RoHS / UL | Meets international quality standards |

Each Copper Braided Wire is manufactured using precision machinery and strict quality control. The braiding density and strand composition are carefully designed to maintain uniform electrical performance across the entire length.

What Are the Benefits of Using Copper Braided Wires?

Using Copper Braided Wires offers numerous performance and operational advantages:

-

Superior Conductivity:

Copper provides outstanding electrical performance, ensuring stable current flow with minimal energy loss. -

Excellent Flexibility:

The braided design allows bending and vibration absorption without cracking or fraying. -

Durability and Corrosion Resistance:

Tin or nickel plating protects the wire from oxidation, extending lifespan even in harsh environments. -

Heat Dissipation:

The open braided structure promotes airflow and reduces heat buildup, enhancing safety. -

Customizability:

Available in flat or tubular shapes, different thicknesses, and lengths to meet specific installation requirements. -

Mechanical Strength:

Designed to handle mechanical stress and thermal expansion in high-current applications.

Where Are Copper Braided Wires Commonly Applied?

Copper Braided Wires are used across various industries and applications, including:

-

Electrical Panels and Switchgear: For grounding and flexible connections.

-

Automotive and EV Systems: Providing high-current connections in battery and motor assemblies.

-

Transformers and Generators: Reducing vibration-related stress on electrical joints.

-

Railway and Aerospace Systems: Ensuring reliability under mechanical movement.

-

Lightning Protection Systems: Grounding conductors for safe discharge of electrical surges.

-

Industrial Equipment: Connecting moving parts like robotic arms and conveyors.

Dongguan Quande Electronics Co., Ltd. ensures that each product is tailored to the customer's exact technical needs, offering both standard and custom designs.

Why Should You Choose Dongguan Quande Electronics Co., Ltd. for Copper Braided Wires?

As a professional manufacturer with years of experience in electrical connectivity solutions, Dongguan Quande Electronics Co., Ltd. focuses on producing high-quality Copper Braided Wires that meet global standards.

Our advantages include:

-

High Precision Manufacturing: Using advanced weaving equipment for consistent braid density.

-

Strict Quality Control: Every batch is tested for resistance, tensile strength, and conductivity.

-

Custom Engineering Solutions: Designs optimized for flexibility, thermal management, and current-carrying capacity.

-

Fast Delivery & Global Supply: Reliable logistics to support international clients.

Our mission is to ensure that every connection you make is safe, efficient, and durable.

FAQ About Copper Braided Wires

Q1: What makes Copper Braided Wires better than solid copper conductors?

A1: Unlike solid conductors, Copper Braided Wires are flexible and can absorb vibration and movement, making them ideal for dynamic applications. They also have better surface contact and lower resistance due to multiple fine strands.

Q2: Are Copper Braided Wires suitable for high-current applications?

A2: Yes. Their high conductivity and excellent heat dissipation make them suitable for high-current systems such as battery packs, transformers, and grounding lines.

Q3: Can Copper Braided Wires resist corrosion and oxidation?

A3: Absolutely. Tin-plated or nickel-plated Copper Braided Wires offer strong protection against corrosion and oxidation, extending their lifespan in humid or industrial environments.

Q4: Does Dongguan Quande Electronics Co., Ltd. provide custom sizes or designs?

A4: Yes. We specialize in custom manufacturing, offering a wide range of cross-sectional areas, braid patterns, and finishes based on specific customer requirements.

How Can You Contact Us for More Information?

If you are looking for high-quality Copper Braided Wires for your project or OEM application, our team is ready to assist. We provide technical guidance, product customization, and fast delivery worldwide.

Trust Dongguan Quande Electronics Co., Ltd. to deliver reliable Copper Braided Wires that enhance performance, safety, and efficiency across your electrical systems.