How Does Copper Braid Enhance Electrical Performance?

2025-08-19

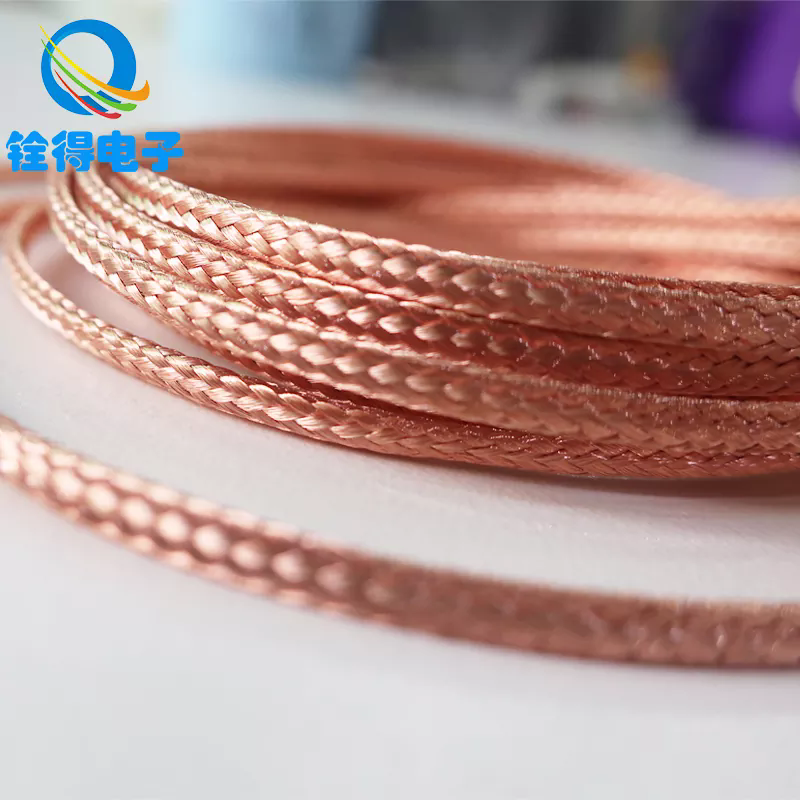

Copper braid is one of the most essential conductive materials used across multiple industries, from electrical power distribution to automotive engineering and aerospace applications. It is made by weaving thin copper wires into a flexible, mesh-like structure. This unique form provides both mechanical flexibility and high electrical conductivity, allowing it to handle current flow efficiently while adapting to movement, vibration, and thermal expansion.

What Makes Copper Braid Different?

Unlike rigid copper busbars or solid conductors, copper braid can bend and flex without compromising performance. This flexibility is why it is widely used in grounding, shielding, bonding, and current transfer applications. The braid absorbs vibration, accommodates misalignment, and provides consistent conductivity even in harsh environments.

Industries value copper braid because of its:

-

Superior Conductivity: Copper offers one of the lowest electrical resistances among metals.

-

Thermal Stability: Withstands high temperatures without losing mechanical strength.

-

Durability: Resistant to corrosion, especially when tinned or silver-plated.

-

Flexibility: Moves with mechanical stress without cracking.

-

Customization: Available in different widths, thicknesses, and constructions.

Key Applications of Copper Braid

Copper braid plays an indispensable role in the following areas:

-

Electrical Grounding – ensures safe current dissipation in substations, buildings, and vehicles.

-

Automotive Industry – supports battery connections, EV charging systems, and noise suppression.

-

Aerospace and Defense – provides EMI/RFI shielding and bonding in sensitive electronic systems.

-

Telecommunication Systems – reduces interference and stabilizes signal quality.

-

Renewable Energy – integrates solar panels and wind turbines with power distribution systems.

The combination of safety, conductivity, and adaptability has made copper braid a standard component wherever electrical reliability is a top priority.

Technical Specifications and Product Parameters

When selecting copper braid, engineers and procurement teams consider precise parameters to ensure performance and compliance with application standards. Below is a summary of typical product specifications.

| Parameter | Details |

|---|---|

| Material | Pure copper (99.9% minimum purity) |

| Finish | Bare copper, tinned copper, silver-plated copper |

| Strand Diameter | 0.05 mm – 0.3 mm (depending on flexibility required) |

| Braid Width | 2 mm – 200 mm |

| Thickness | 0.5 mm – 6 mm |

| Cross-Sectional Area | 1 mm² – 500 mm² |

| Electrical Conductivity | ≥ 97% IACS (International Annealed Copper Standard) |

| Current Carrying Capacity | 10 A – 2000 A (application-dependent) |

| Operating Temperature Range | -40°C to +200°C |

| Standards | RoHS compliant, IEC, ASTM, UL recognized |

Why These Parameters Matter

-

Material Purity ensures maximum conductivity and long-term reliability.

-

Tinned or Silver Plating provides additional corrosion resistance.

-

Strand Diameter determines flexibility; finer wires mean smoother bends.

-

Cross-Sectional Area relates directly to current-carrying capacity.

-

Operating Range ensures functionality under extreme conditions.

These specifications enable engineers to match the correct braid type to project requirements.

How Copper Braid Improves Safety and Performance

Electrical Grounding and Bonding

One of the most critical uses of copper braid is in grounding. Electrical systems require a safe pathway for fault currents. Copper braid acts as that path, preventing dangerous buildup and ensuring compliance with electrical codes.

Bonding applications also rely on braid. By connecting metallic structures together, copper braid eliminates potential differences and reduces the risk of sparks or static discharge.

Shielding Against Electromagnetic Interference (EMI)

In industries where sensitive electronics operate, electromagnetic interference can cause data loss, malfunctions, or signal disruption. Copper braid provides effective EMI shielding, absorbing and redirecting interference to ground. This feature is especially important in aerospace, defense, and telecommunication sectors.

Durability in Harsh Environments

From underground mines to offshore wind farms, copper braid withstands temperature swings, moisture, and vibration. When tinned or silver-plated, it resists oxidation and retains performance even in corrosive atmospheres.

Mechanical Flexibility and Vibration Absorption

Rigid conductors crack under constant movement. Copper braid, however, adapts to continuous bending and vibration, making it perfect for:

-

Automobile engines with constant vibration.

-

Railway systems experiencing repetitive mechanical stress.

-

Industrial robots where cables bend thousands of times daily.

Cost-Effectiveness in Long-Term Applications

While initial costs may be slightly higher compared to other materials, copper braid provides long-term savings by reducing maintenance, preventing downtime, and extending equipment life.

FAQs, Market Outlook, and Brand Connection

Copper Braid FAQs

Q1: What is the difference between tinned copper braid and bare copper braid?

A1: Bare copper braid offers excellent conductivity but is more susceptible to oxidation over time. Tinned copper braid has a thin protective tin coating that enhances corrosion resistance, making it better suited for outdoor or humid environments. Both types maintain high conductivity, but tinned copper braid ensures longer service life under challenging conditions.

Q2: How do I choose the correct size of copper braid for my application?

A2: The correct size depends on current requirements, voltage, and installation conditions. Engineers usually calculate based on cross-sectional area and current-carrying capacity. For grounding applications, larger widths and thicknesses are preferred to handle fault currents. For EMI shielding, smaller, more flexible braids may be selected. Consulting product parameter tables helps ensure correct sizing.

Global Market and Future Trends

The demand for copper braid is expanding rapidly due to:

-

Electrification of Transportation – Electric vehicles rely heavily on grounding and power transfer solutions.

-

Renewable Energy Growth – Solar and wind installations require durable and efficient current carriers.

-

Telecommunication Expansion – 5G and high-speed internet systems depend on EMI protection.

-

Automation and Robotics – Flexible conductors are vital in dynamic industrial systems.

Sustainability also influences production. Many manufacturers now ensure copper braid is RoHS compliant, environmentally safe, and recyclable.

Brand Mention and Call to Action

At the heart of the copper braid supply chain are trusted manufacturers who combine precision engineering with global compliance standards. Among these, Quande stands out for its dedication to producing high-purity, customizable copper braid solutions tailored to diverse industries.

If your business requires reliable copper braid for grounding, shielding, or bonding applications, Quande offers product ranges that align with strict quality benchmarks. Our team is ready to assist with technical consultations, custom orders, and fast delivery worldwide.

Contact us to discuss how Quande can support your projects with industry-leading copper braid solutions.